Asia’s Tallest Temple to be Built in Ahmedabad, India

Posted on May 31, 2022

As a symbol of faith and reverence in the tutelary deity Maa Umiya, Vishv Umiya Foundation has taken on the challenging task of building the tallest temple in Asia, and one of the tallest temples in the world at 144m. UmiyaDham is rooted in the ancient Vedic traditions. It has been touted as being a distinctive place where the devotee will be able to gather and experience the tranquil divinity.

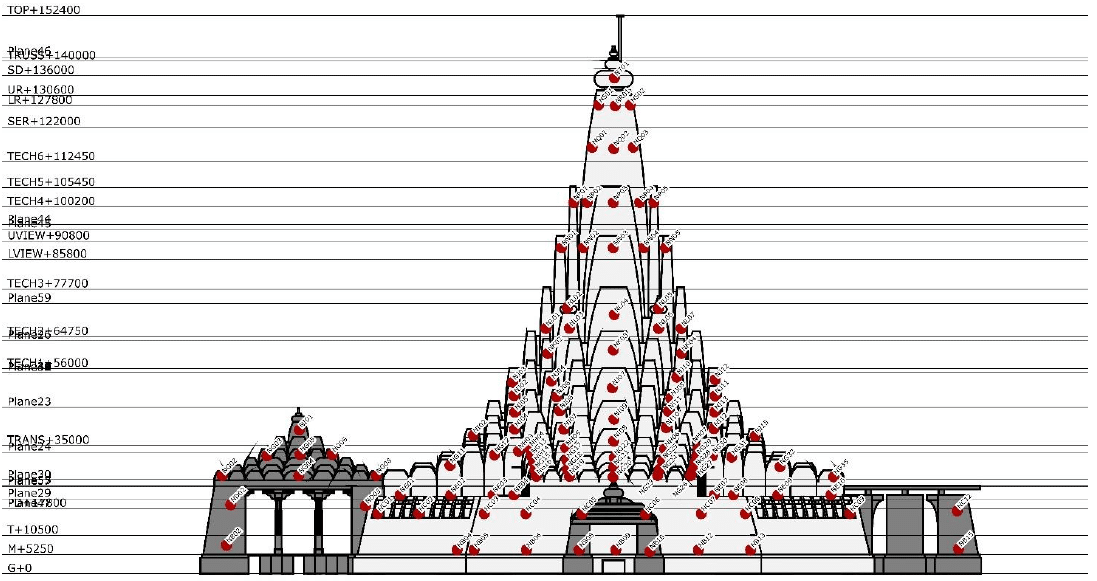

Figure 1. Image of Vishv Umiadham Temple (Image courtesy of the Vishv Umiya Foundation)

The temple is planned for city of Ahmedabad (near Vaishno Devi circle) on land admeasuring 60 acres, and is budgeted to cost over Rs. 10 billion to build. Along with the temple it will be house a socio-economic empowerment hub for our community’s well-being.

Given the complexity of the building form and the apparent structural design constraints, the consultancy team, made up of Colliers as Project Manager and Kling Consult as the Structural Consultant, were acutely aware that the structure and cladding systems could not be designed using basic code-based principles, and that a performance-based wind design approach was needed.

Aaron Lefcovitch who covers Windtech’s projects in Asia comments that “Codes only address the typical case and applying code-based principles for a building as complicated as the Vishv Umiadham Temple Project could potentially be misleading, assuming the designer does not properly compensate for the fact that there is a significant departure from the regular form. It is not unusual for us to conduct a code-based desktop analysis and structural data reviews. We do this on most of our projects as part of a QA process and first glance at expected, albeit usually slightly conservative loads and accelerations. This helps us align with the structural engineer early on in our program, however, care must be taken in the application of code-based wind desing. In general, the code can be used when the height to minimum with ratio is less than 5:1, when the natural frequency is higher than 0.2Hz, and when the building height does not exceed 150m (i.e. as per the Indian Standard IS875). In some circumstances, we may refer to coefficient data obtained from past testing of similar structures, however in general the above principles still apply.

As part of the commission for this project, Windtech was appointed to carry out the following wind tunnel studies which assisted in the efficient design of the structural and cladding systems as well as the ensuring adequate wind conditions in all the critical outdoor areas:

- A Structural Loads & Building Motion Study was carried out using High-Frequency Pressure Integration (HFPI) Techniques. The use of the HFPI technique enables an accurate and definitive determination of the vertical distribution of the wind loads taking into consideration the impact that closely coupled modes have on the response. The technique also allows for the quick update to the analysis assuming a revised set of dynamic properties. From the study, it was found that the base overturning moments obtained through wind tunnel testing were almost half those predicted by the Indian Standard IS875-3:2015. There were also sizable reductions in the magnitude of the peak tip deflections and acceleration. This provided the structural engineering significant opportunity to optimise the structural system which would ultimately result in reduced construction costs.

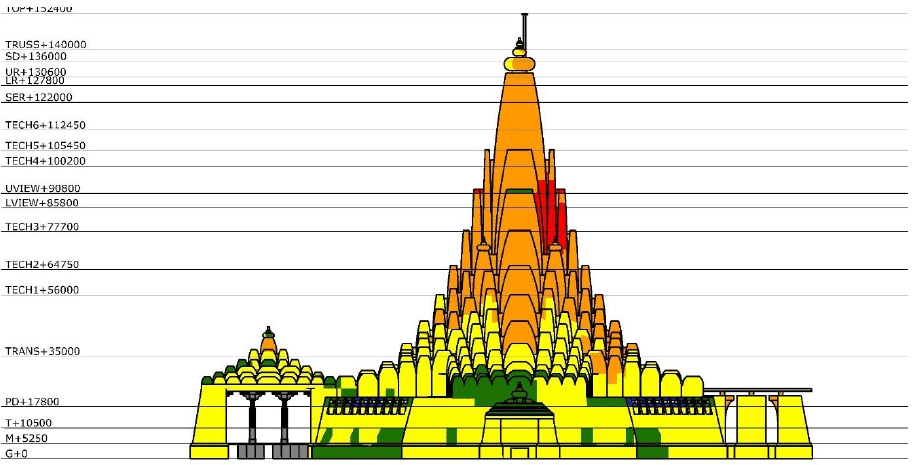

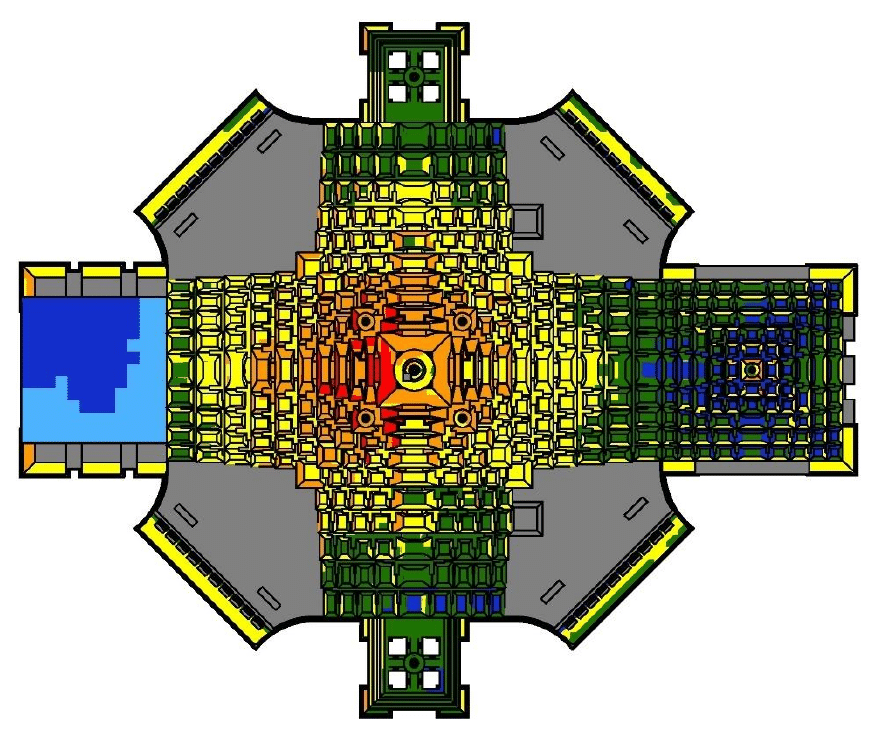

- A Façade Cladding Pressure study was undertaken to obtain the full-scale pressure distribution over the entire building envelope. A total of 722 pressure sensors were installed in the model as shown in Figure 2 to obtain accurate distribution of the surface pressure gradients. The pressure contours were presented in 2D format in the report as well as on a virtual 3D model in “block contour” format which is a unique capability to Windtech Consultants. A figure showing the distribution of pressure on the surface of the building is seen in Figure 3. The study showed that 90% of the façade had 50year pressures within the range of +1.8kPa to -1.9kPa which is a significant reduction over code-based results. This allowed for the thickness optimisation of the lightweight cladding elements for the majority of the facade, while being able to pick out the small regions of pressure which potentially exceeded the code predictions requiring slight reinforcement.

- A Wind Environment Study was also undertaken. The results from the study indicated that wind conditions for all areas around and within the site mostly satisfied comfort and safety limit criteria with the exception of one location which was easily mitigated through the strategic placement of a screen/ planter box. This highlighted the relative ease in identifying potential adverse wind conditions which were addressed during the design stage, rather than adopting expensive remedial solutions post-construction.

Figure 2. Layout of Pressure Sensors

Figure 3a. Elevation Drawing with Pressure Contours

Figure 3b. Roof Plan Drawing with Pressure Contours

We would like to congratulate the team made up of Vishv Umiya Foundation, Colliers, Kling Consult, and many others for pulling off this unique and innovative award-winning project. It is truly an iconic temple and will be for the next 500 years.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

Return to Main News Page