Figure 1. Aerial Image of Lake Shore Boulevard West Development

Occupying the 28-acre former Mr. Christie factory site, the development by First Capital REIT and Pemberton Group will transform the western lakeshore into a mixed-use, transit-oriented precinct anchored by a new integrated GO Station and TTC Hub. The plan includes multiple residential and commercial towers—several exceeding 200 m in height—together with retail, offices, and extensive public realm improvements that reconnect the city with the waterfront.

Windtech’s wind engineers delivered comprehensive wind tunnel testing, wind-induced structural load and motion testing, and façade cladding pressure studies for the first 3 towers, all conducted in its Sydney-based boundary-layer wind tunnel, utilising the firm’s advanced multi-sector analysis method to post-process the results. Windtech also conducted thermal stack-effect assessments for the towers. The studies were instrumental in shaping an aerodynamically efficient design that met stringent comfort and serviceability criteria while minimising material use, cost, and embodied carbon.

Precision Engineering and Performance-Based Design

The studies covered Towers C1 (154 m), D1.1 (223 m), and D2.1 (212 m), all slender residential structures rising from shared podiums.

Windtech’s multi-sector analysis of climate directionality proved pivotal in demonstrating that these slender towers can meet the limits on tip deflections and occupant comfort. By integrating aerodynamic responses across the various wind sectors, our wind engineers avoided the built-in conservatism inherent in sector-by-sector analysis.

This precision offered more than data accuracy; it was a form of risk mitigation. For towers operating near their motion limits, the ability to identify the exact wind sectors driving those peak responses allowed the structural engineer to fine-tune the structure without resorting to conservative redesign. In practical terms, the analysis avoided the need for costly supplemental dampers or structural thickening that often follows when less-sophisticated directional methods are used.

The outcome was a set of refined equivalent static load cases that faithfully represented the true aerodynamic behaviour of each tower, supporting both design confidence and material efficiency, a rare combination in high-rise performance engineering.

Cost and Embodied-Carbon Efficiencies

The design optimisations derived from Windtech’s wind tunnel testing resulted in substantial material savings. By proving that the towers could perform safely within serviceability and comfort criteria with no significant modification to the proposed structural system, the engineers eliminated the need for additional stiffening of the cores or the introduction of heavy outriggers, leading to:

These efficiencies demonstrate how performance-based wind design/testing can drive both economic and environmental outcomes—a key advantage in the development of this scale.

Façade and Environmental Studies

A wind tunnel study of the façade pressures used more than 1,000 sensors to map localised load effects across façades, balconies, soffits, and podium elements. Contours of maximum and minimum net pressures are presented in the report in a format that facilitates the design of the cladding and glazing systems.

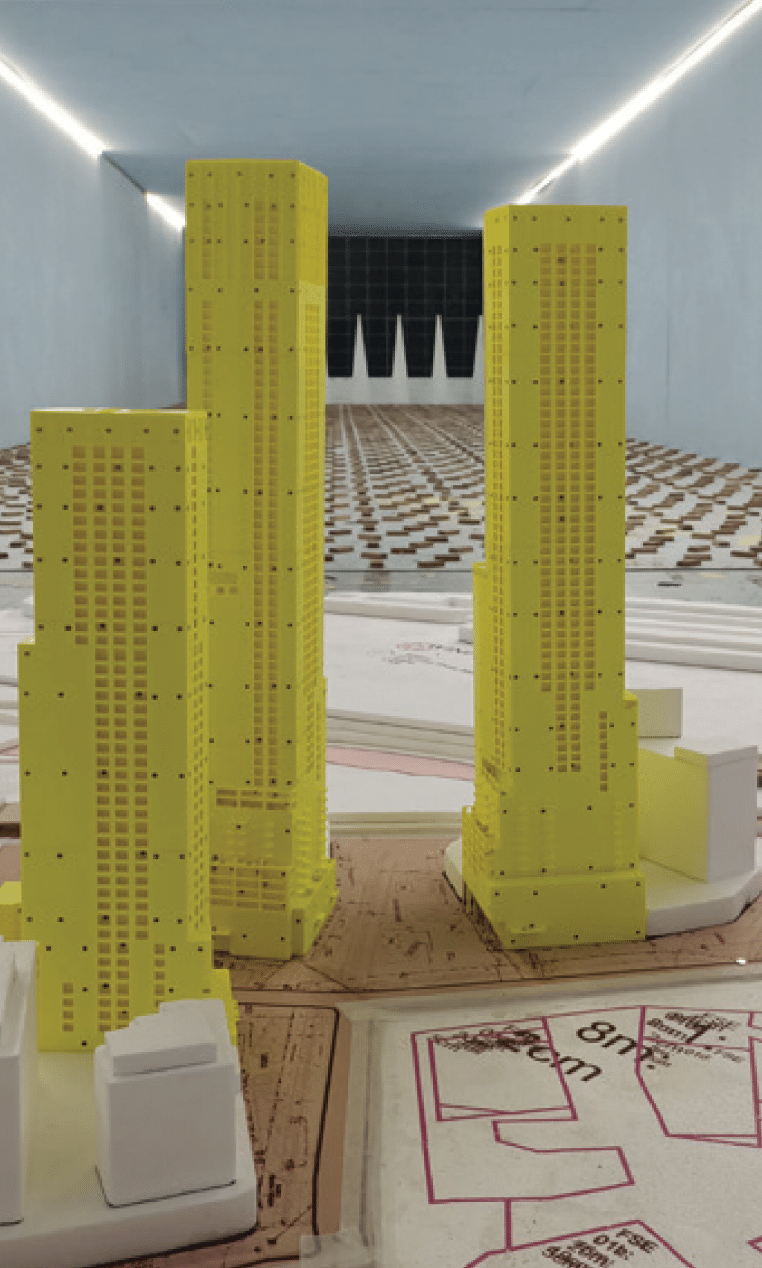

Figure 2. Close up photo of the instrumented models in Windtech’s boundary layer wind tunnel facility

Meanwhile, stack-effect modelling identified wintertime pressure differentials at elevator lobbies and podium entries. Mitigations such as added vestibules and segmented lift lobbies were incorporated, ensuring occupant comfort and efficient HVAC operation year-round

A Holistic, Low-Impact Outcome

By integrating aerodynamic optimisation, façade pressure mapping, and environmental airflow analysis, Windtech’s wind engineers enabled the project team to achieve high-rise resilience with minimal material intensity. The studies ensured:

The 2150 Lake Shore Boulevard West development now stands as an exemplar of how advanced wind engineering can align sustainability, performance, and design economy, proof that smart data beats brute strength.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

We would like to extend our congratulations to Besley & Spresser on receiving the National Commercial Medal at the Concrete Institute of Australia 2025 Excellence in Concrete Awards for the Pier Pavilion at Barangaroo. Windtech is delighted to have collaborated with B&S, delivering tailored wind tunnel studies for this unique harbourside hub. The Pavilion is a striking architectural landmark designed to inspire both connection and creativity.

As part of our involvement in the Pier Pavilion at Barangaroo, Windtech conducted a Pedestrian Wind Environment Wind Tunnel Study to assess wind conditions at key outdoor areas within and around the development. Testing was carried out at Windtech’s boundary layer wind tunnel facility using a 1:400 scale model of the Pavilion. The wind tunnel study confirmed that wind conditions across the critical outdoor locations would be suitable for their intended use, with no adverse impacts identified.

In addition, Windtech provided valuable inputs for the determination of wind loading for the structural design of the Pavilion

Ready to tackle your next complex wind engineering challenge? Discover how Windtech’s innovative wind tunnel studies can transform your project’s performance and efficiency. Please contact our regional offices through our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page

Figure 1: Perspective Image of Terminal F at Dallas-Fort Worth Airport

When Dallas Fort Worth International Airport set out to build Terminal F, it wasn’t just adding another gate; it was engineering a solution to handle 100 million passengers annually by 2030. However, with a massive long-span roof and a complex skylink system, traditional wind load calculations wouldn’t suffice.

That’s where Windtech Consultants stepped in, working alongside PGAL Architects, Innovation Next+, and Turner to solve what would become one of the most sophisticated wind engineering challenges in modern airport design, using state-of-the-art wind tunnel testing.

Terminal F presented a unique engineering puzzle. The expansive terminal structure and elevated skylink system created complex wind interaction patterns that standard approaches couldn’t adequately predict. The long-span upper roof, positioned at the terminal’s heart, demanded a level of precision essential for the project’s structural efficiency.

Traditional analysis methods would have resulted in overly conservative designs, which would have driven up costs and potentially compromised the architectural vision. The team needed something better.

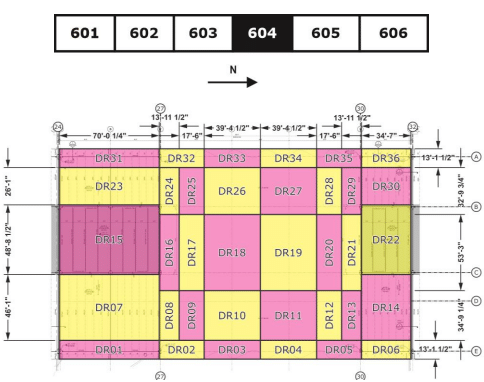

Windtech adopted the multi-sector analysis technique, which is the most rigorous method of combining the wind tunnel testing pressure coefficient data with the local wind climate model. In addition, the area-averaging method was used to accurately determine the loading on the main structural members, an industry-recognised approach for translating detailed wind tunnel testing data into actionable design loads. Rather than focusing on isolated peak pressures at individual points, the area-averaging method considers the combined effect of pressures distributed across larger panels of the structure as indicated in Figure 2. This provides a more realistic representation of how these large structural members experience wind actions.

By carefully defining representative panel sizes and shapes across the terminal envelope, our team delivered wind-induced load cases that accurately reflect the building’s true behaviour under extreme winds from different directions. The outcome: reliable, rationalised pressure distributions that give the structural engineer confidence, avoid overly conservative assumptions, and contribute to a more efficient, cost-effective design.

Figure 2. Panel Layout for Roof of Sector 604 of Terminal F at DFW

The scope extended far beyond structural loads. Windtech conducted exhaustive facade cladding pressure studies across every surface of both the terminal and skylink system, ensuring no detail was overlooked. A comprehensive wind tunnel testing process and wind microclimate assessment evaluated how the new terminal would affect ground-level conditions, protecting passenger comfort and operational efficiency.

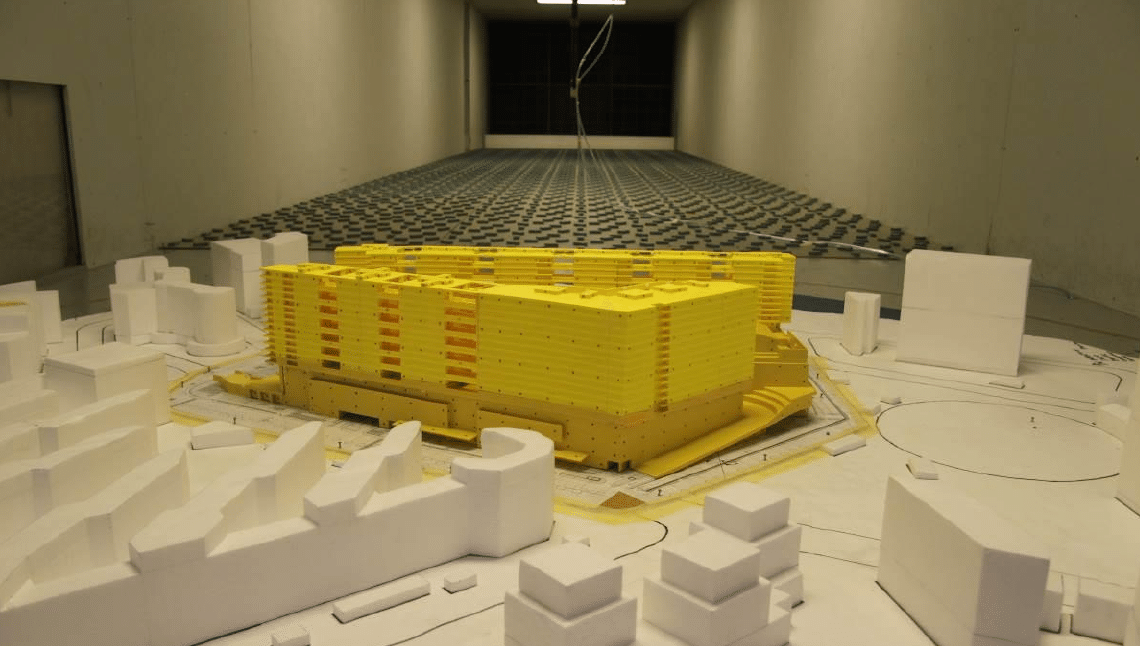

Figure 3. Wind Tunnel Testing Model Terminal F at DFW

Aviation projects face a unique challenge that most buildings don’t: Federal Aviation Administration oversight of solar reflectivity. Terminal F’s modern facade and rooftop photovoltaic arrays required careful analysis to prevent solar glint and glare from affecting pilots during critical approach and departure phases.

Windtech’s Solar Light Reflectivity Analysis identified potential problem areas and guided design modifications, ensuring full FAA compliance while maintaining the terminal’s striking architectural aesthetic.

Terminal F now stands as a testament to what’s possible when advanced engineering meets ambitious architecture. The project demonstrates how thoughtful wind tunnel testing and wind engineering can unlock architectural possibilities while delivering measurable value through improved structural efficiency. For an industry where safety, performance, and cost-effectiveness are non-negotiable, Terminal F represents the future of intelligent design.

Ready to tackle your next complex wind engineering challenge? Discover how Windtech’s innovative wind tunnel testing approaches can transform your project’s performance and efficiency. Please contact our regional offices through our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page

Located in the wind-exposed coastal environment of Surfers Paradise, the Cypress Avenue Towers are a landmark high-rise development that demonstrates how performance-based wind engineering can unlock value across design, construction, and long-term operational performance. With Towers 1 and 2 reaching heights of 304 and 261 metres respectively, the complex presented unique engineering challenges.

Windtech Consultants provided a comprehensive suite of services. The team engaged at every stage of the design process—from initial form-finding and code compliance assessments to detailed testing for structural and cladding performance, stack effect, paver uplift, and comfort conditions. Each tower was evaluated under multiple staging scenarios using scaled wind tunnel models and high-resolution proprietary pressure instrumentation. The result was a suite of tailored wind engineering solutions that informed nearly every major design decision.

This project is a clear example of how early engagement with an experienced wind engineering team, such as Windtech, can yield significant dividends in design efficiency, cost savings, and quality outcomes. Developer Meriton, acutely aware of these benefits, sought Windtech’s input from the outset.

At approximately 303 metres (993 feet), the tallest of the Cypress Avenue Towers is set to become the second-tallest building in Australia by highest occupiable floor. With an aspect ratio of 11:1, it posed particular aerodynamic and structural challenges. Windtech initiated the project by reviewing three alternative tower massings, ultimately identifying a preferred scheme due to its superior aerodynamic performance, which resulted in structural cost savings per unit area. This recommendation, backed by preliminary desktop assessments, was adopted by the client and confirmed via wind tunnel testing.

Structural form and wind loads were assessed using Windtech’s hybrid aeroelastic model, offering higher accuracy and cost-effectiveness over the simple aeroelastic models. This method captured positive aerodynamic damping effects, which reduced the overall peak response by 6%. Motion along the tower’s weaker axis was also mitigated through a cost-neutral solution involving the shaping of two 67,000-litre rooftop fire hydrant tanks to act as tuned liquid dampers.

Windtech collaborated closely with the structural engineering team to refine the dynamic response of the towers under wind loading. High-Frequency Pressure Integration (HFPI) testing was conducted on a 1:400 scale model with 36 wind directions and realistic terrain features. Each tower was assessed under three scenarios—Staged, Proposed, and Future—providing comprehensive data on wind demands over time.

Compared to AS1170.2:2021 estimates, wind tunnel-derived ULS base moments for the critical cross-wind governed responses were reduced by 36% to 77%. Torsion loads were reduced by 45% to 60%.

These reductions enabled the design team to optimise structural systems, including shear wall thickness and core reinforcement. Besides the performance-based benefits, the Australian code would not permit a code-based design for the development of this height and slenderness.

Serviceability limit state (SLS) displacements remained within H/500 in all directions, confirming sufficient stiffness without overdesign. Peak accelerations remained within comfort thresholds, with sensitivity analysis provided to demonstrate the effect of variations in frequency, mass, and damping, thereby showing robust design performance.

Importantly, the staged analysis confirmed minimal adverse interactions between towers, validating the phased construction strategy without requiring significant redesign.

Damping requirements were evaluated to ensure occupant comfort, with detailed analysis confirming that no supplemental damping was required at the design stage. However, the foundation was laid for future design decisions should damping solutions become necessary. A decision was made by Meriton, as developer, to shape the fire hydrant tanks to act as tuned liquid dampers to provide an added level of amenity over and above the stipulated criteria, understanding that human sensitivity to building motion varies substantially from one person to another.

Windtech’s pressure study used 1,311 sensors on a 1:400 scale model tested under both Proposed and Future conditions. Data from 36 wind directions was weighted using long-term Bureau of Meteorology data.

Key findings:

Windtech also used surface pressure coefficients to calculate annual mean pressures on HVAC vents and assess paver uplift. These coefficients fed into the stack effect analysis and informed waterproofing detailing.

Wind environment testing targeted the ground plane, podium, and balcony zones. Gust velocities were compared to thresholds for seating, standing and walking comfort.

Wind mitigations included strategic placement of screens, planting as well as positioning of pergolas and gazebos on the podium. In addition, vertical blade walls were introduced for the colonnade and porous screening on sections of the podium enclosing the car parking areas. These interventions were validated by comparative re-testing.

Windtech modelled the stack effects generated under the 99-percentile extreme winter and summer temperatures and with the corresponding high and low wind conditions. Stack effect study identified pressures exceeding the 50Pa capacity of the lift doors at the top floor of the shorter tower (Level 76) as well as a wind entry issue for the entry to the taller tower from podium (Level 6).

For Level 76 of the shorter tower, pressures were mitigated by eliminating lift doors and providing stair access from Level 75 to the private rooftop terraces. Wind entry issues at the entry to the taller tower from the podium were resolved using a canopy and side screens.

Windtech assessed local uplift of the proposed pedestal paver tiles, accounting for the partial pressure equalisation of the proposed paver system (referring to Windtech’s library of its own full-scale test data). The report recommended that the 600×600-20mm pavers (cavity depths ranges from 25mm to 130mm) be interconnected in groups of at least 2 x 3 to be able to resist uplift.

A comprehensive wind noise review was undertaken, examining potential noise from louvres, breeze walls, and balcony screens. Recommendations were made for the internal partition walls and internal doors to avoid them generating noise during high wind event. Minor design changes were proposed to the balcony screen arrangements to prevent Helmholtz resonance.

Windtech’s holistic approach has resulted in a high-quality, integrated and efficient design:

Windtech’s contribution to the Cypress Avenue Towers underscores the value of comprehensive, high-quality, integrated wind engineering. Across structural, façade, mechanical, and environmental comfort domains, Windtech’s unmatched depth of experience and rigorous testing enabled a high-quality design outcome.

This performance-based approach reduced conservatism, improved buildability, and enhanced the occupant experience. The Cypress Avenue Towers exemplify how tall buildings can be designed not just to resist wind, but to provide a positive all-around experience for the occupants.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

Figure 1. Photo of Jio World Centre (Courtesy of Reliance)

Figure 1. Photo of Jio World Centre (Courtesy of Reliance)

In the dynamic heart of Mumbai’s financial district stands a project that marries ambition with performance, the Jio World Centre, formerly known as the Dhirubhai Ambani International Convention and Exhibition Centre (DAICEC). The development is as complex as iconic with its expansive exhibition halls, elevated towers, lush terraces, and vibrant public spaces. Behind its iconic form lies the work of a dedicated team of wind engineers, whose precision-driven analysis helped transform this mega-development into a model of comfort, resilience, and sustainability.

The Jio World Centre has been envisioned as a platform where the best of India and the world converge. Nita Mukesh. Ambani, Founder and Managing Director of Reliance Industries Limited (RIL), articulated this vision: “A tribute to our glorious nation, we hope that the Jio World Centre will be a platform where the best of India and the world will meet. A place for cultures and communities to come together and script a new chapter in India’s growth story.”

Since its launch, the Jio World Centre has hosted numerous significant events. As reported by the International Congress and Convention Association (ICCA)

“In the fiscal year 2022-23, Jio World Centre hosted over 800 events, generating a footfall of 1,900,000+. This comprised a diverse mix of conventions, exhibitions, corporate meetings, product launches along with social and live events.” Subsequent has seen growth in these numbers.

Figure 2. Image of Jio World Centre being tested in one of Windtech’s Wind Tunnels

But behind the architecture is a deeper engineering narrative driven by performance, precision, and sustainability. As experienced wind engineers, Windtech Consultants ensured that every development component, structural, façade, and environmental, was rigorously tested and optimised for real-world wind conditions. What resulted was a textbook example of how performance-based design can drive down material wastage, construction costs, and embodied carbon, all while enhancing comfort and safety.

“Our aim wasn’t just to meet minimum design requirements—it was to help the design team realise their architectural vision without compromise, while also reducing structural inefficiencies and environmental impact,” said Aaron Lefcovitch, Director at Windtech Consultants.

Located in Mumbai’s Bandra Kurla Complex, the development is surrounded by high-rise neighbours like the Bharat Diamond Bourse, the Trident Hotel, and the U.S. Consulate. Its proximity to Mahim Bay and Mumbai’s complex wind climate presented a unique set of aerodynamic challenges. With monsoonal gusts, dense urban roughness, and pedestrian-level sensitivities, wind effects must be understood in all dimensions.

Windtech began by creating a 1:400 scale physical model of the entire precinct, including a 500 m-radius proximity model of surrounding buildings. The model was tested in Windtech’s 3.0 m-wide boundary layer wind tunnel, which simulates real-world atmospheric wind flow. Each test was conducted with a high level of fidelity, informed by many years of meteorological data from Mumbai’s Santacruz station.

Figure 3. Aaron Lefcovitch, Director (Left) and Anjana Krishna, Senior Project Manager (Right), Windtech

Structural safety was paramount, but so was economy and sustainability. Windtech conducted a full suite of wind-induced structural load studies for this multi-tower development using the pressure integration technique. Over 991 sensors on the towers captured time-synchronised wind pressures across 36 wind directions.

Rather than relying on overly conservative code-based estimations, we delivered a performance-based design approach that provided realistic wind forces on the tower based on its actual geometry,” Aaron explained. “This allowed structural engineers to reduce reinforcement, concrete volumes, and member sizes where appropriate, without compromising safety and economy.”

Figure 4. Photo of Jio World Centre (Courtesy of JWCC)

Figure 4. Photo of Jio World Centre (Courtesy of JWCC)

This targeted approach reduced the total structural material quantities, contributing directly to lower embodied carbon and construction cost savings. Importantly, the loads captured dynamic interactions between the towers and podium, allowing engineers to avoid overdesign while ensuring structural resilience.

Windtech also performed an extensive façade cladding pressure study for the 50-year return period wind event. This included testing 1,081 façade sensors and 438 differential pressure pairs to capture net pressures across parapets, crown features, awnings, soffits, and cooling towers.

The results were presented as detailed pressure zoning diagrams, pinpointing high-pressure “hot spots” versus low-stress regions. This enabled the façade consultants to tailor the thickness and fixing of cladding materials only where needed, rather than applying conservative assumptions uniformly.

“If you know exactly where the wind loads peak—and where they don’t—you can design smarter,” said Aaron. “This approach reduced steel and aluminium use across the façade systems, which not only saved money but also reduced the carbon footprint of the building envelope.”

The study also accounted for internal pressurisation effects from exhaust vents, louvers, and leakage paths, ensuring that pressure coefficients used in design were realistic, not idealised.

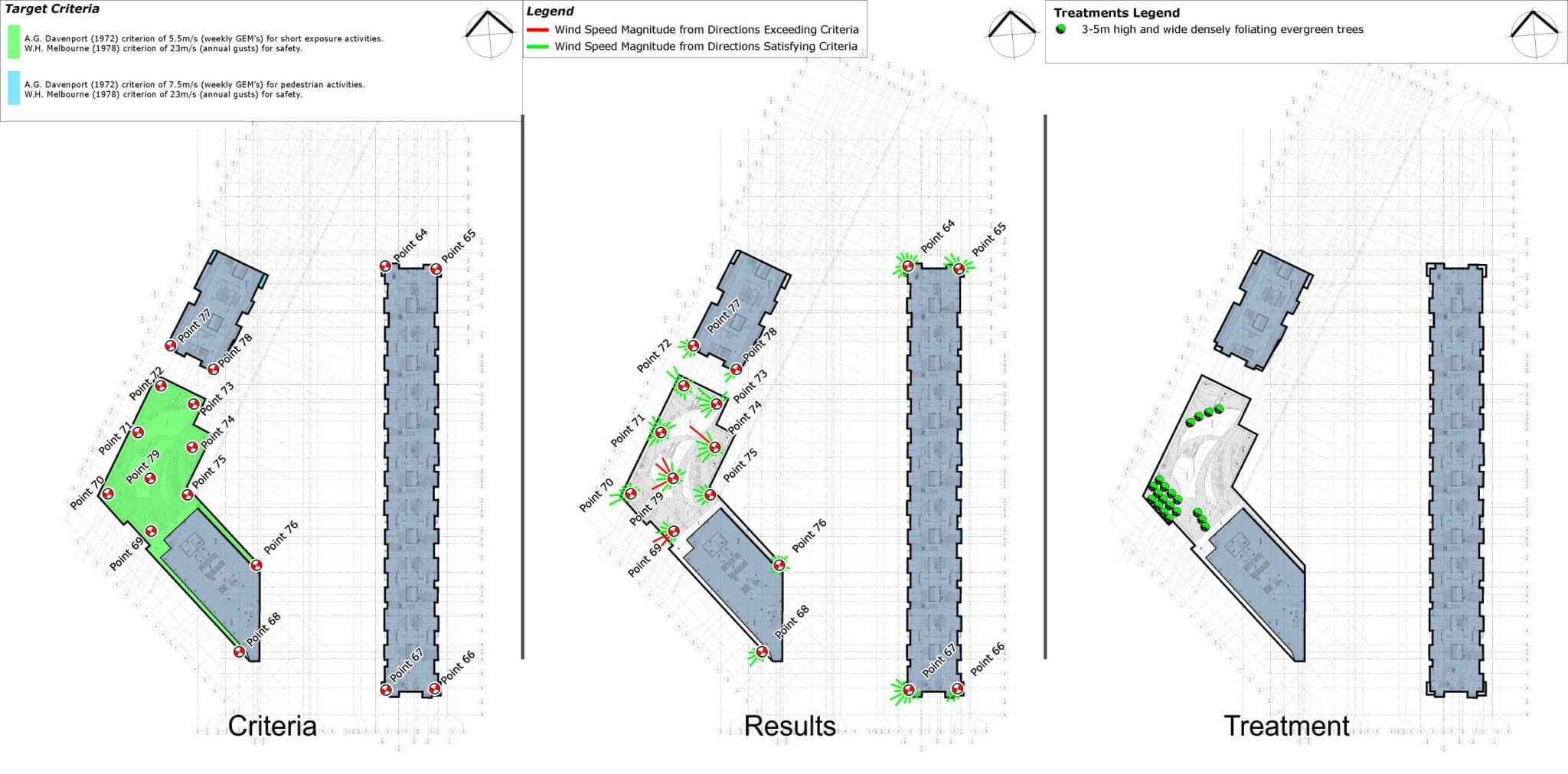

Windtech’s Pedestrian Wind Environment (PWE) study focused on ensuring all outdoor areas, from terraces to ground-level pathways, met comfort and safety thresholds under annual and weekly maximum wind conditions. This involved measuring both mean and gust wind speeds at key pedestrian zones.

Initial testing identified a few high-wind areas, particularly around elevated balconies and roof terraces. Rather than overhauling the design, Windtech proposed strategic wind amelioration features, including:

Figure 5. Pedestrian Wind Comfort Criteria, Results & Treatments for Level 12 Office Tower Terrace

These recommendations were retested and refined in the tunnel, resulting in a verified improvement to comfort conditions. The interventions were subtle, yet effective, allowing for open-air amenity spaces without excessive enclosure or visual obstruction.

One of the most nuanced studies undertaken was Windtech’s investigation of internal wind flows through over 300 serviced apartments and atrium spaces.

Windtech predicted mean internal air velocities for various opening configurations by combining external pressure data with internal layout geometry. The goal was to ensure that indoor spaces remained calm, safe, and free from disruptive drafts, even during peak weekly wind conditions.

All results showed compliance with occupant comfort thresholds, with mean internal velocities below 1 m/s. This reassured the design team that natural ventilation strategies could be implemented without causing discomfort or interior disruption.

“Internal airflow control is often overlooked—but it’s critical to the livability of high-rise spaces, especially in humid climates like Mumbai,” Aaron noted.

Across each study, Windtech worked with Reliance Industries, architects, structural consultants, and façade engineers. The collaborative environment empowered real-time design iterations, where proposed mitigations could be tested and validated without delay.

“Reliance had a strong vision, but they also valued technical input,” said Aaron. “They weren’t afraid to test, question, and refine. That’s the kind of mindset that leads to landmark developments.”

From structure to skin and street to skyline, the wind engineering strategies embedded in the Jio World Centre reflect a sustainability-forward approach grounded in data, discipline, and dialogue.

By embracing performance-based wind tunnel testing, the project team achieved:

The result is a building that performs as beautifully as it looks, resilient, refined, and ready for decades of safe, sustainable use.

If you are working on any projects that could benefit from the capabilities presented in this article, please contact our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.