Figure 1. Photo of Jio World Centre (Courtesy of Reliance)

Figure 1. Photo of Jio World Centre (Courtesy of Reliance)

In the dynamic heart of Mumbai’s financial district stands a project that marries ambition with performance, the Jio World Centre, formerly known as the Dhirubhai Ambani International Convention and Exhibition Centre (DAICEC). The development is as complex as iconic with its expansive exhibition halls, elevated towers, lush terraces, and vibrant public spaces. Behind its iconic form lies the work of a dedicated team of wind engineers, whose precision-driven analysis helped transform this mega-development into a model of comfort, resilience, and sustainability.

The Jio World Centre has been envisioned as a platform where the best of India and the world converge. Nita Mukesh. Ambani, Founder and Managing Director of Reliance Industries Limited (RIL), articulated this vision: “A tribute to our glorious nation, we hope that the Jio World Centre will be a platform where the best of India and the world will meet. A place for cultures and communities to come together and script a new chapter in India’s growth story.”

Since its launch, the Jio World Centre has hosted numerous significant events. As reported by the International Congress and Convention Association (ICCA)

“In the fiscal year 2022-23, Jio World Centre hosted over 800 events, generating a footfall of 1,900,000+. This comprised a diverse mix of conventions, exhibitions, corporate meetings, product launches along with social and live events.” Subsequent has seen growth in these numbers.

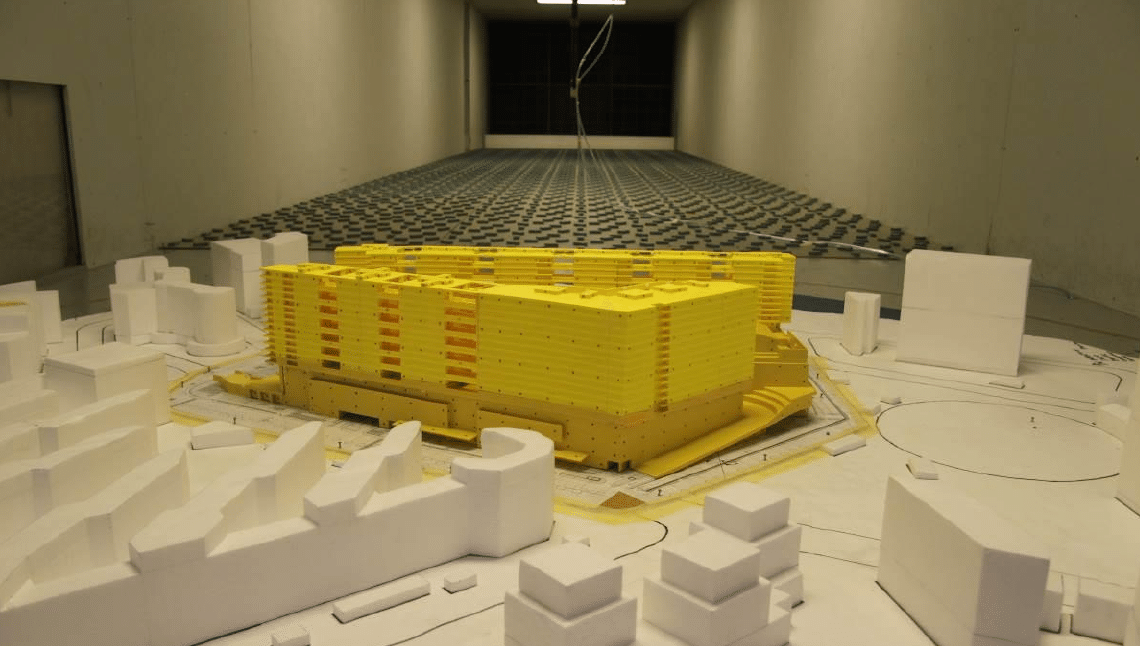

Figure 2. Image of Jio World Centre being tested in one of Windtech’s Wind Tunnels

But behind the architecture is a deeper engineering narrative driven by performance, precision, and sustainability. As experienced wind engineers, Windtech Consultants ensured that every development component, structural, façade, and environmental, was rigorously tested and optimised for real-world wind conditions. What resulted was a textbook example of how performance-based design can drive down material wastage, construction costs, and embodied carbon, all while enhancing comfort and safety.

“Our aim wasn’t just to meet minimum design requirements—it was to help the design team realise their architectural vision without compromise, while also reducing structural inefficiencies and environmental impact,” said Aaron Lefcovitch, Director at Windtech Consultants.

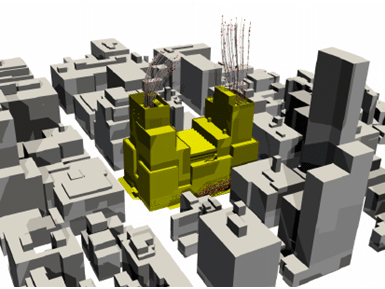

Located in Mumbai’s Bandra Kurla Complex, the development is surrounded by high-rise neighbours like the Bharat Diamond Bourse, the Trident Hotel, and the U.S. Consulate. Its proximity to Mahim Bay and Mumbai’s complex wind climate presented a unique set of aerodynamic challenges. With monsoonal gusts, dense urban roughness, and pedestrian-level sensitivities, wind effects must be understood in all dimensions.

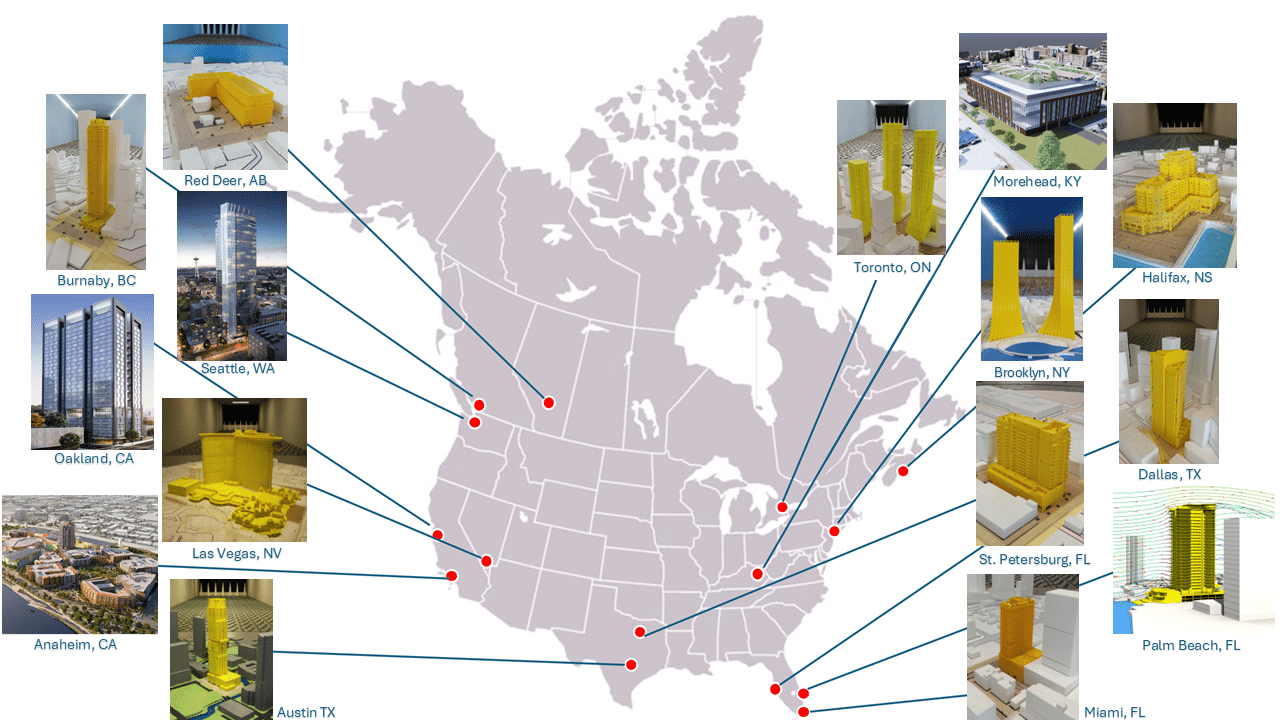

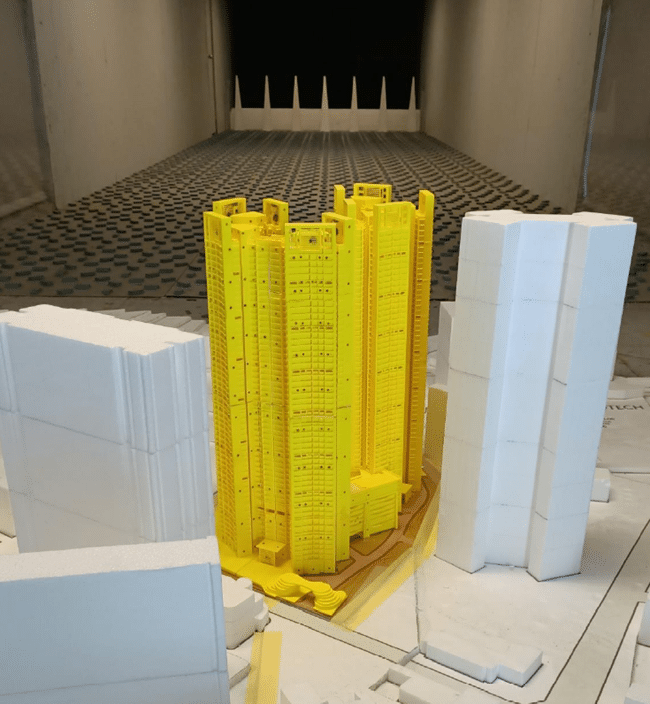

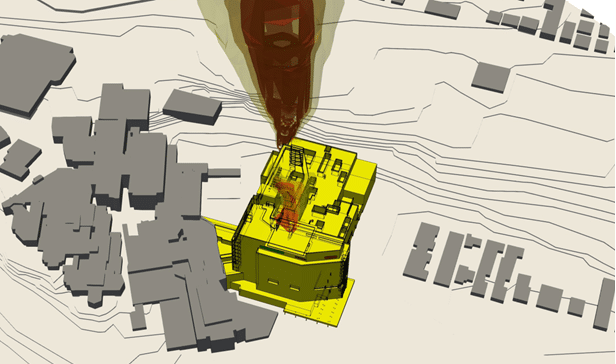

Windtech began by creating a 1:400 scale physical model of the entire precinct, including a 500 m-radius proximity model of surrounding buildings. The model was tested in Windtech’s 3.0 m-wide boundary layer wind tunnel, which simulates real-world atmospheric wind flow. Each test was conducted with a high level of fidelity, informed by many years of meteorological data from Mumbai’s Santacruz station.

Figure 3. Aaron Lefcovitch, Director (Left) and Anjana Krishna, Senior Project Manager (Right), Windtech

Structural safety was paramount, but so was economy and sustainability. Windtech conducted a full suite of wind-induced structural load studies for this multi-tower development using the pressure integration technique. Over 991 sensors on the towers captured time-synchronised wind pressures across 36 wind directions.

Rather than relying on overly conservative code-based estimations, we delivered a performance-based design approach that provided realistic wind forces on the tower based on its actual geometry,” Aaron explained. “This allowed structural engineers to reduce reinforcement, concrete volumes, and member sizes where appropriate, without compromising safety and economy.”

Figure 4. Photo of Jio World Centre (Courtesy of JWCC)

Figure 4. Photo of Jio World Centre (Courtesy of JWCC)

This targeted approach reduced the total structural material quantities, contributing directly to lower embodied carbon and construction cost savings. Importantly, the loads captured dynamic interactions between the towers and podium, allowing engineers to avoid overdesign while ensuring structural resilience.

Windtech also performed an extensive façade cladding pressure study for the 50-year return period wind event. This included testing 1,081 façade sensors and 438 differential pressure pairs to capture net pressures across parapets, crown features, awnings, soffits, and cooling towers.

The results were presented as detailed pressure zoning diagrams, pinpointing high-pressure “hot spots” versus low-stress regions. This enabled the façade consultants to tailor the thickness and fixing of cladding materials only where needed, rather than applying conservative assumptions uniformly.

“If you know exactly where the wind loads peak—and where they don’t—you can design smarter,” said Aaron. “This approach reduced steel and aluminium use across the façade systems, which not only saved money but also reduced the carbon footprint of the building envelope.”

The study also accounted for internal pressurisation effects from exhaust vents, louvers, and leakage paths, ensuring that pressure coefficients used in design were realistic, not idealised.

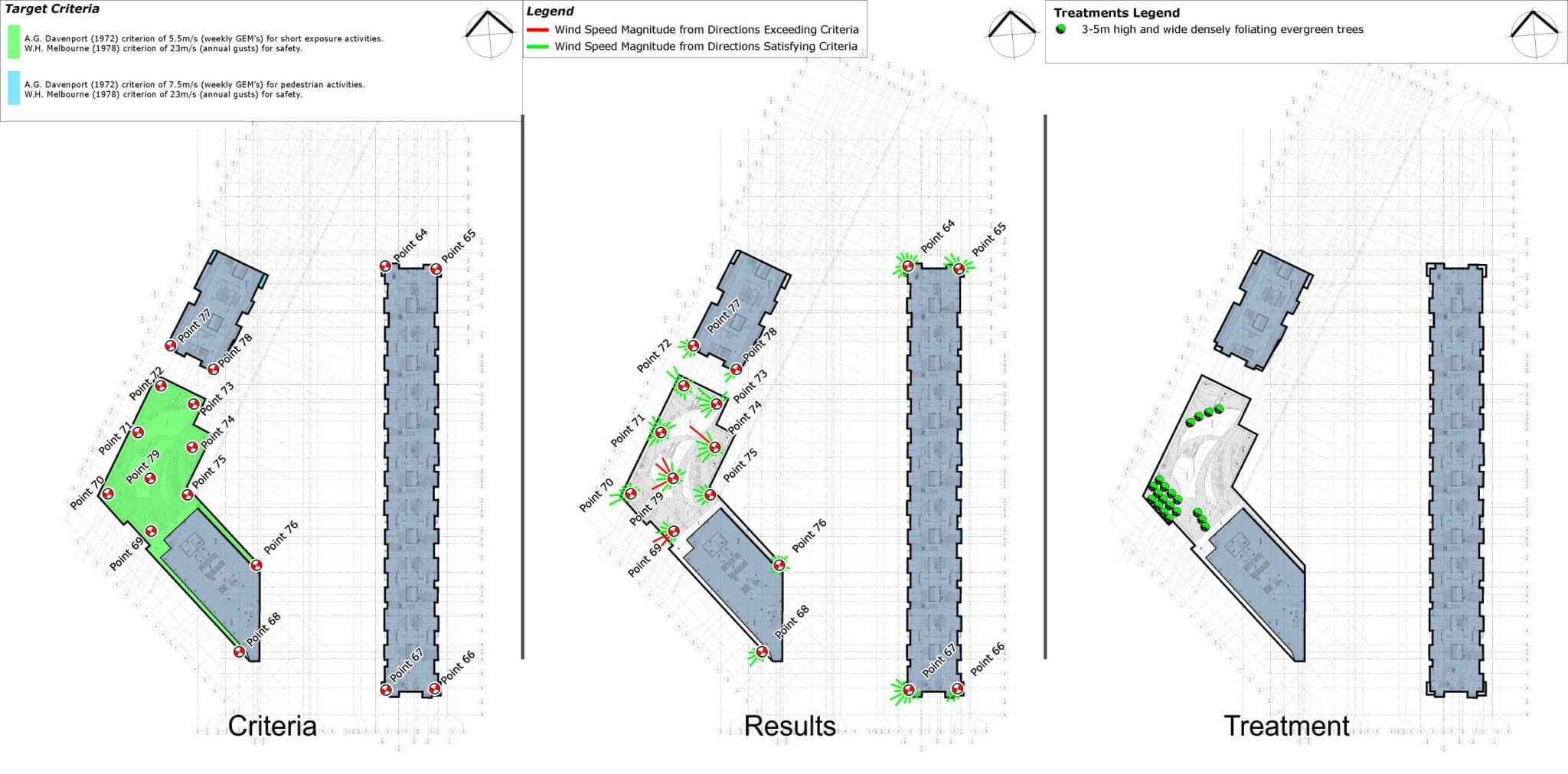

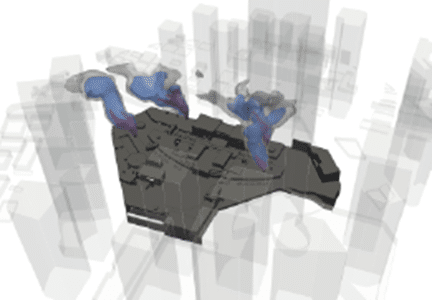

Windtech’s Pedestrian Wind Environment (PWE) study focused on ensuring all outdoor areas, from terraces to ground-level pathways, met comfort and safety thresholds under annual and weekly maximum wind conditions. This involved measuring both mean and gust wind speeds at key pedestrian zones.

Initial testing identified a few high-wind areas, particularly around elevated balconies and roof terraces. Rather than overhauling the design, Windtech proposed strategic wind amelioration features, including:

Figure 5. Pedestrian Wind Comfort Criteria, Results & Treatments for Level 12 Office Tower Terrace

These recommendations were retested and refined in the tunnel, resulting in a verified improvement to comfort conditions. The interventions were subtle, yet effective, allowing for open-air amenity spaces without excessive enclosure or visual obstruction.

One of the most nuanced studies undertaken was Windtech’s investigation of internal wind flows through over 300 serviced apartments and atrium spaces.

Windtech predicted mean internal air velocities for various opening configurations by combining external pressure data with internal layout geometry. The goal was to ensure that indoor spaces remained calm, safe, and free from disruptive drafts, even during peak weekly wind conditions.

All results showed compliance with occupant comfort thresholds, with mean internal velocities below 1 m/s. This reassured the design team that natural ventilation strategies could be implemented without causing discomfort or interior disruption.

“Internal airflow control is often overlooked—but it’s critical to the livability of high-rise spaces, especially in humid climates like Mumbai,” Aaron noted.

Across each study, Windtech worked with Reliance Industries, architects, structural consultants, and façade engineers. The collaborative environment empowered real-time design iterations, where proposed mitigations could be tested and validated without delay.

“Reliance had a strong vision, but they also valued technical input,” said Aaron. “They weren’t afraid to test, question, and refine. That’s the kind of mindset that leads to landmark developments.”

From structure to skin and street to skyline, the wind engineering strategies embedded in the Jio World Centre reflect a sustainability-forward approach grounded in data, discipline, and dialogue.

By embracing performance-based wind tunnel testing, the project team achieved:

The result is a building that performs as beautifully as it looks, resilient, refined, and ready for decades of safe, sustainable use.

If you are working on any projects that could benefit from the capabilities presented in this article, please contact our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

As the building and construction industry evolves in response to climate imperatives, the focus is rapidly expanding beyond operational efficiency to include embodied carbon—the emissions associated with the materials and construction processes used to bring a building to life.

Governments, certification bodies, and developers worldwide are setting ambitious targets for carbon reduction. Yet one often-overlooked contributor to embodied carbon savings is the wind engineer. By optimising a building’s aerodynamic performance early in the design process, it’s possible to reduce the structural demands—and in turn, the materials needed—without compromising on design or functionality.

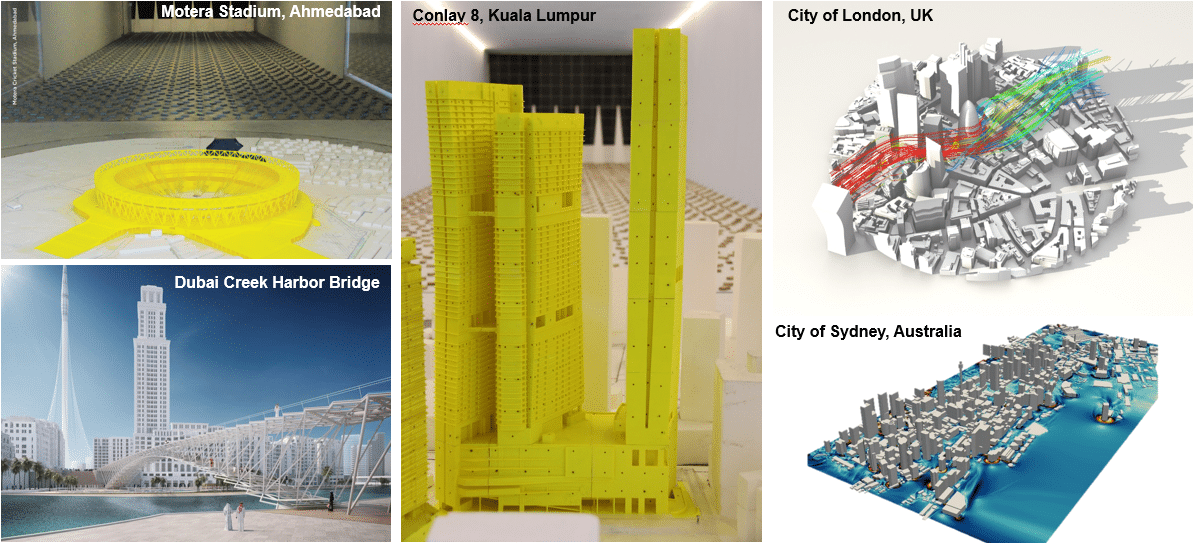

At Windtech Consultants, we’ve worked on over 3,000 projects globally and have found that strategic aerodynamic interventions and advanced methods can lead to construction cost savings and embodied carbon reductions of 10–20% or more.

The call for embodied carbon reduction is coming from all corners of the world. Here are just a few examples of frameworks driving this change:

These policies represent a growing shift: it’s not just how we operate buildings that matters—it’s how we build them.

The link between wind loads and structural materials is direct. Higher wind loads require heavier structural systems, which increases both cost and embodied carbon—especially in concrete and steel.

By engaging wind engineers early in the design process, developers can make subtle form adjustments or staging decisions that reduce wind loads, allowing the structure to be leaner, lighter, and lower in emissions.

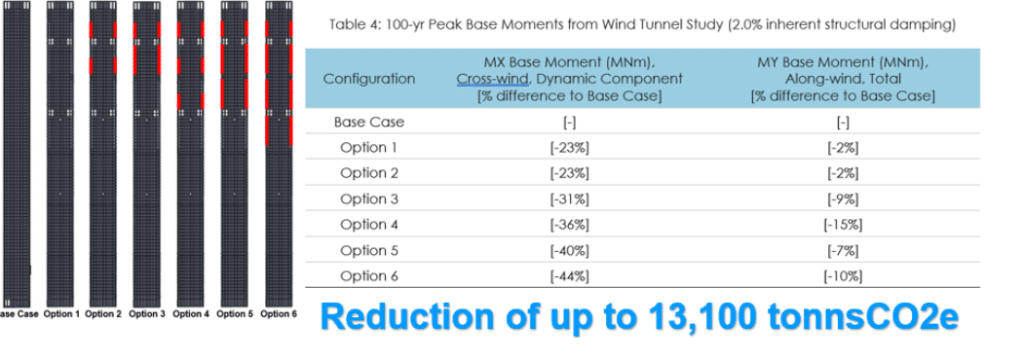

13,100 Tons of Embodied Carbon Saved Through Aerodynamic Refinement

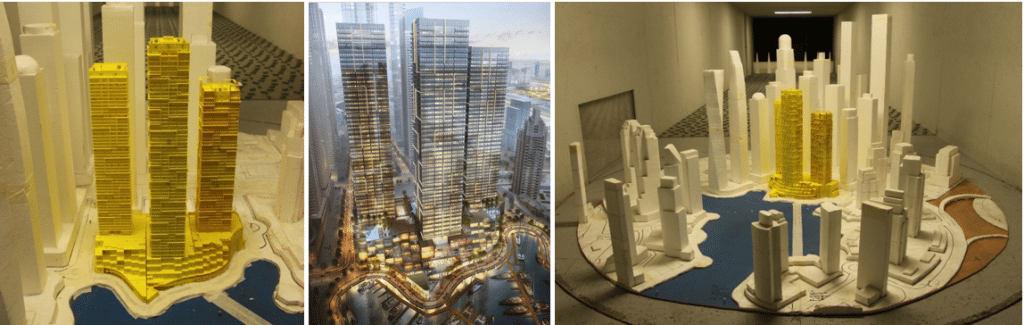

SRG Tower, a 350-metre residential tower in Dubai’s city core, exemplifies how early aerodynamic optimisation can drive down embodied carbon.

Figure 1. Coherent Vortex Shedding of a Square Plan Building

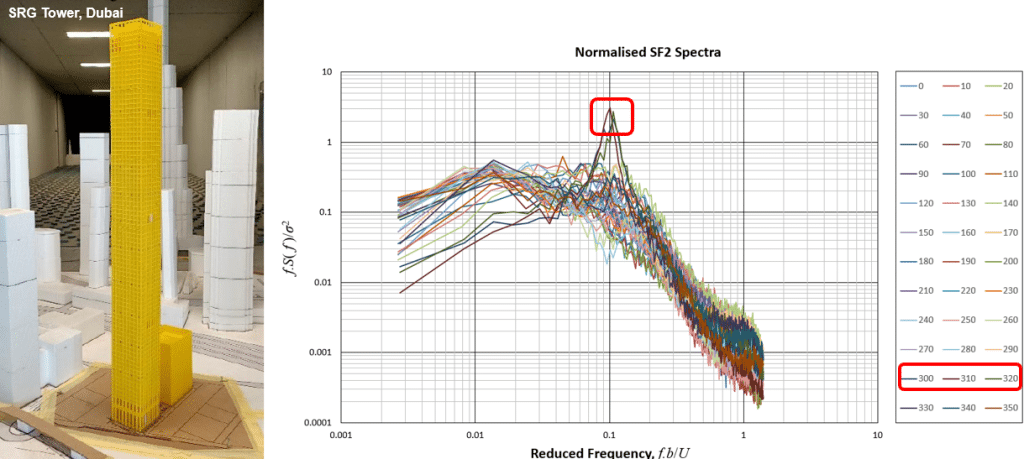

The original scheme featured a square plan with an extremely slender profile (aspect ratio 12:1), rising to 1150 feet. Wind tunnel testing revealed significant cross-wind excitation—particularly around the 310° wind direction, which aligns with Dubai’s prevailing wind. The issue was traced to vortex-induced oscillation, a common phenomenon in slender towers, where wind vortices shed alternately from either side of the building, causing sway.

Figure 2. Response Spectra Showing Excitation at 310° and Adjacent Angles

The architect and developer were averse to significant alterations to the architectural form, which constrained Windtech to find a more subtle solution. The team ruled out using tuned mass dampers, reducing the building height, or implementing large cutouts due to concerns over cost, delays, and loss of floor area.

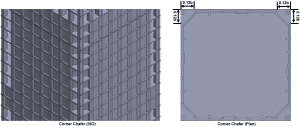

Windtech proposed a dual-strategy approach:

Figure 3. Recommended Corner Chamfers

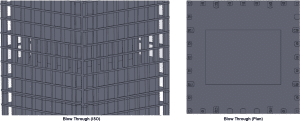

2. Open Service Floors – Strategic placement of open floors at specific levels allowed the wind to pass through, further reducing the dynamic suction effect on side walls. The number of such floors was minimised to maintain leasable area and building efficiency.

Figure 4. Recommended Blow-through Holes

A parametric study involving six different treatment configurations was performed using a single physical model, cleverly adapted with masking tape to toggle configurations. This enabled rapid testing and accurate comparisons.

Figure 5. Parametric Study of 6 Design Options (Red: Corner Chamfer)

This was accomplished without changing the building’s visual identity. This case is a textbook example of how wind engineers can work within tight design constraints and still deliver major carbon savings.

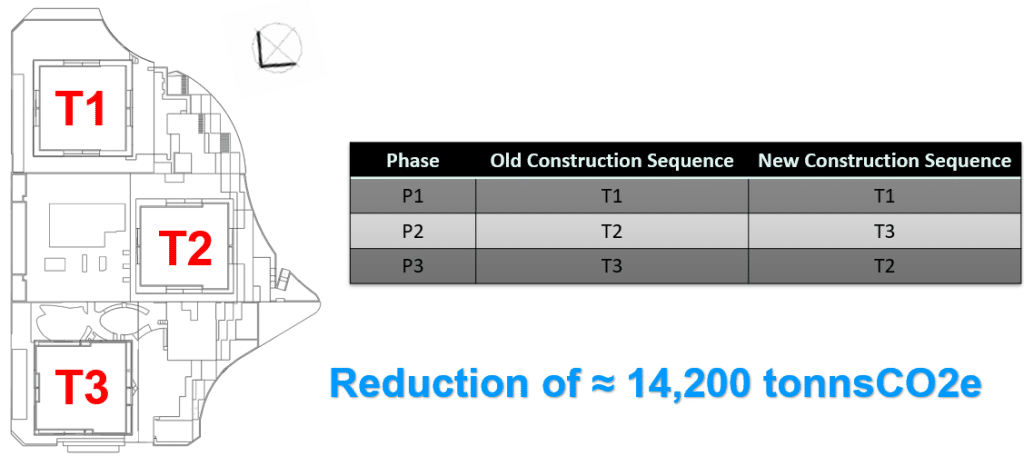

14,200 Tons of Embodied Carbon Avoided with a Simple Change in Construction Staging

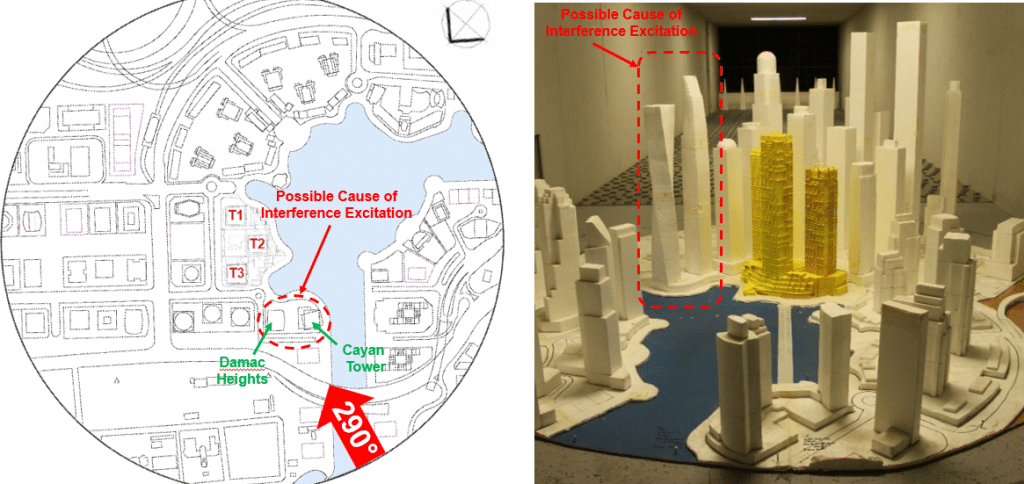

In a separate Dubai-based development, Windtech’s wind engineers were engaged to study a high-rise precinct involving several towers of varying height and orientation. Upon testing, one tower—Tower 2—displayed unexpected wind-induced excitation at the 290° wind direction.

Figure 6. Image of Marina Gate, Dubai is one of Windtech’s Wind Tunnels

Initial analysis showed that the tower wasn’t being excited by its own shape, but rather by interference effects from nearby completed towers, particularly the adjacent Cayan Tower and Damac Heights.

Figure 7. Interference Excitation Caused by Cayan Tower and Damac Heights

The response levels exceeded acceptable comfort and performance thresholds, and without intervention, would have required a costly and time-consuming redesign. This could have meant thicker core walls, more structural bracing, or even changes to the tower’s height or orientation—all options with significant embodied carbon implications.

However, there was a twist: Tower 2 was scheduled to be built before Tower 3, even though Tower 3 was positioned in such a way that it could disrupt the wake turbulence causing the problem.

Windtech proposed a simple but effective solution—reverse the phasing and build Tower 3 first.

Figure 8. Revised Construction Sequencing

When tested with Tower 3 in place, the aerodynamic interference was drastically reduced:

This avoided a complete overhaul of the structural design and saved both time and materials.

This case highlights how a minor change in construction sequence—guided by wind engineering analysis—can deliver major sustainability wins with no impact on design or project schedule.

Windtech’s work across Asia, the Middle East, Europe, and North America has shown that the best carbon reduction strategies are often the least disruptive. Tools we commonly use include:

When applied at the concept or schematic stage, these strategies can significantly improve the project bottom line, reduce the amount of embodied carbon and avoid post-design fixes or costly retrofits.

As the global building industry works toward carbon neutrality, embodied carbon is becoming a central concern. The wind engineer—once seen primarily as a compliance partner for occupant comfort—is now emerging as a key ally in achieving net-zero carbon goals.

When developers engage wind engineers early, they unlock the opportunity to:

At Windtech, we believe in designing smarter, not heavier. As we move toward a low-carbon future, the role of the wind engineer will only become more critical in ensuring that buildings are both resilient and responsible.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

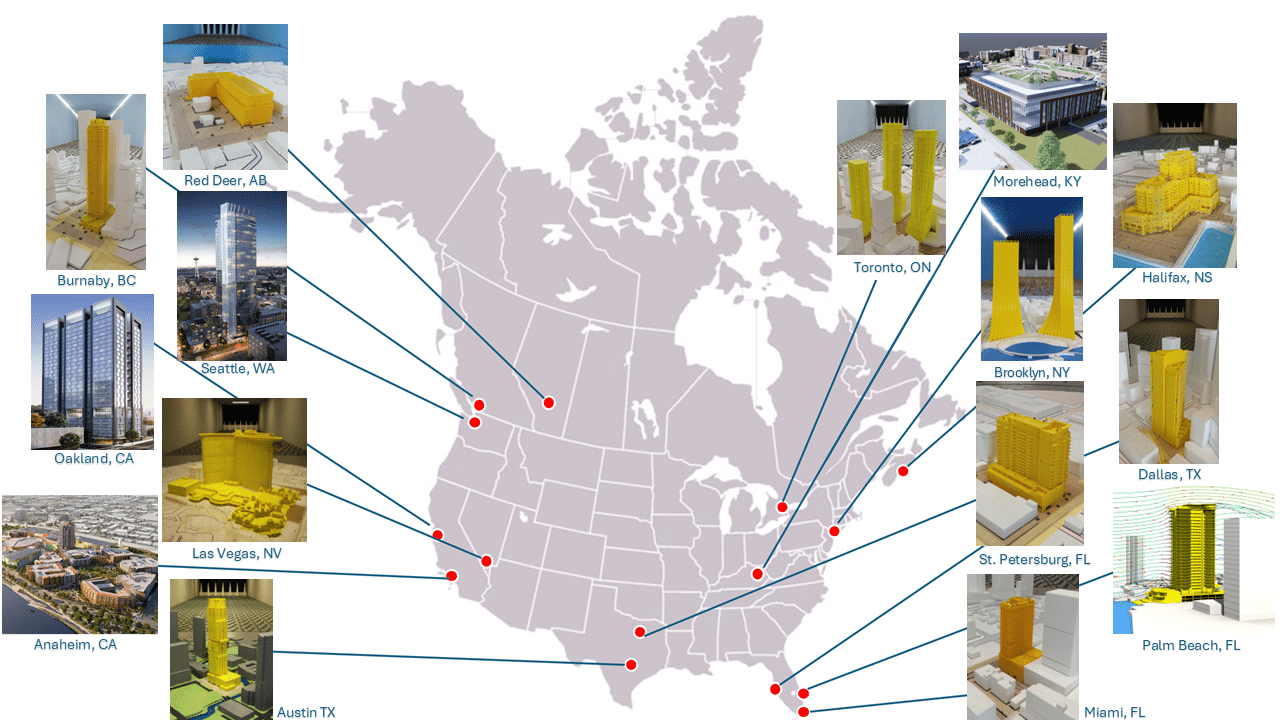

A message from Stefan Gopaul, Associate Director | Regional Manager, Canada & USA:

Windtech’s extensive wind engineering experience has seen over 3,000 completed projects world-wide and its high-service culture has been shown in the form of cost-effective, innovative solutions deployed on numerous projects across North America. Windtech’s wind engineering services have become highly sought after by clients in Canada and the United States and has become a major player for wind consulting in the region. Our growing portfolio in both markets has allowed us to expand our reach across both countries, with regional offices located in Toronto, New York, and Miami. Our portfolio is not limited to these cities but includes projects in four Canadian provinces and eight major US states, which is an achievement we are proud of.

Whether supporting responsible urban development through pedestrian-level wind comfort studies in Southwestern Ontario; contributing to effective high-rise building resilience in extreme wind climates, such as South Florida, Texas, New York, Los Angeles or the Greater Toronto Area, through wind-induced structural loads and façade cladding pressure studies; supporting critical infrastructure projects such as airport terminals in Dallas-Fort Worth; or ensuring clean and safe environmental and building air quality in a hospital in Red Deer, Alberta, a university in Morehead, Kentucky, an office park in Manhattan or a residential complex in Queens; Windtech has worked on numerous high-profile Canadian and US projects that have bolstered our reputation in both regions as a market leader in the field of wind engineering and building physics/CFD modelling.

We look to continue to build new partnerships and strengthen existing ties with leading developers, architects, and engineering consultants, to show our commitment to the region, and will continue to bring a strong foundation built around cutting-edge wind engineering principles and a client-focused vision.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional offices Sydney & Melbourne, Australia, London, UK, and Mumbai, India. New York & Miami, USA, Toronto, Canada, Dubai, Hong Kong & Singapore, we guarantee to support you wherever you are based.

To get regular updates on news and events, please follow us on our LinkedIn page.

Prestige Bellanza Residences stands as a landmark development in Mumbai, symbolizing modern architectural elegance and quality by the Prestige Group. Comprised of six 54-story high-rise towers atop seven podium levels, Bellanza is an impressive addition to the city’s skyline. This residential project is designed to set new standards in urban living in Mulund with its grand scale and meticulous attention to design. Situated in one of India’s busiest metropolises, Bellanza showcases contemporary aesthetics combined with structural precision, making it a standout addition to the city skyline. It reflects Prestige Group’s commitment to creating monumental, transformative spaces that redefine luxury and sophistication in Mumbai’s residential landscape.

Windtech worked alongside Prestige Group to provide wind advice to deliver tailored wind analysis and design recommendations that optimize the performance of Bellanza’s high-rise structures. Our assessments involved conducting a detailed analysis of the regional wind climate to set the boundary conditions for the various wind tunnel studies conducted. In order to properly simulate the wind flow structures at scale, a 1:400 scale model of the target buildings was manufactured using 3D Printers. A model of the surrounding buildings and land topography was also built representing the general surrounding building massing up to 500m away from the site location

In order to obtain the pressure gradients across the surface of all the buildings 1,955 pressures were installed, each with the ability to measure the pressures at a sample rate of more than 2,000 samples per second. To put this into perspective, across the entire project, the total number of measurements acquired was upwards of a few billion, assuming normal scale model sample times. Aaron Lefcovitch, a Director based out of Windtech Singapore Office goes on to say that, “the pressure system used in our facility is quite unique as it was built in-house from the best available components. In addition to this, we had developed advanced proprietary signal conditioning algorithms that allow us to measure pressure from more than 1,100 pressure sensors simultaneously with exceptional signal-to-noise ratios, and at high sample rates and low phase lag. It is akin to comparing a high-quality sound system to a mid-tier system. The high-quality system has as far greater depth of fidelity, and this greatly affects its accuracy”.

In addition to obtaining the pressures on the cladding of the buildings, the same pressure system is used for determining the wind forces on the structure, and the building accelerations (i.e Building Sway – affecting occupant comfort). The High Frequency Pressure Integration (HFPI) Technique was used allowing for the accurate assessment of wind force, accounting for both translational and torsional response impacts. Windtech’s HFPI results align closely with full-scale data (see Texas Tech Experimental Building Study), demonstrating industry-leading accuracy down to ±5%. Some of the conclusions drawn from the study were as follows:

Another commission was a detailed wind environment study to evaluate pedestrian comfort and safety across outdoor areas. The study identified high wind zones, particularly on the rooftop terrace of Wing D, where wind speeds exceeded comfort criteria. Recommendations included installing 1.5m high impermeable balustrades to mitigate wind impacts and ensuring compliance with wind comfort and safety standards. With these measures, Windtech concluded that all areas would meet pedestrian comfort and safety requirements, highlighting their commitment to enhancing the usability of outdoor spaces.

Prestige Bellanza demonstrates how cutting-edge engineering and thoughtful design can transform the design and construction of tall buildings. The collaboration between Windtech Consultants and the Prestige Group highlights the importance of integrating advanced wind engineering into high-rise developments to ensure safety, comfort, and sustainability. This case study serves as a benchmark for future projects, showcasing the seamless blend of innovation, precision, and luxury that defines the modern urban landscape.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional offices Sydney & Melbourne, Australia, London, UK, and Mumbai, India. New York & Miami, USA, Toronto, Canada, Dubai, Hong Kong & Singapore, we guarantee to support you wherever you are based.

To get regular updates on news and events, please follow us on our LinkedIn page.

Air quality is often managed through prescriptive rules, generally in terms of minimum separation distances between the sources and accessible areas. There is generally no consideration in these rules for the potential effect of the pollutant being channelled by the wind for example in a gap between two podiums or entrapment of the discharge within a large catchment due to significant shielding of the source location from the prevailing winds.

Windtech offers performance-based solutions that are able to address not only the above shortcomings but allow for flexibility in the design given the many constraints faced by a designer when choosing to locate the discharge locations for a commercial kitchen, carpark exhaust or a standby power generator.

Windtech’s unique approach includes the provision of initial high-level input at the early design stages based on the local wind climate, the proposed building form and shielding by surrounding buildings and topography. Once the design has been sufficiently frozen, more detailed quantitative studies are undertaken against established exposure standards using only or more of the following methods:

For any of the above techniques, Windtech is able to make recommendations for the improvement and management of exposure levels where required to meet specific regulations for the protection and comfort of the building’s inhabitants and the greater public. The test is repeated to confirm the effectiveness of the mitigation strategies.

Case Studies

An example of an air quality study undertaken using the wind tunnel flow visualization technique is the study of an industrial kitchen exhaust located below a communal terrace. The flow visualization indicates that the discharge tends to be carried up then shears down the façade onto the terrace. The solution involving a canopy over the terrace has been demonstrated to be effective (see the image below).

Figure 1: Testing of the canopy treatment as part of a 2011 flow visualisation study for the exhaust from an industrial kitchen in the Saigon Center, HCMC.

Examples of studies undertaken using the wind tunnel spectrometry technique are the SUNY Optometry Building and the Red Deer Regional Hospital. See images of the wind tunnel models below.

Figure 2: SUNY Optometry, New York, NY

Figure 3: Red Deer Regional Hospital (RDRH) Ambulatory Building, Alberta, Canada

Examples of studies undertaken using the computational fluid dynamics modelling method are the study of various discharges including a standby power generator from the Frankston Hospital in Melbourne, Disney HQ at 4 Hudson New York for the study of the rooftop boiler exhaust stream and the TRX Retail Plot 1, Kuala Lumpur for the study of odour dispersion (see Figures 4 to 6 below)

Figure 4: Frankston Hospital, Victoria, Australia – CFD Model Study for one of the sources

Figure 5: (Left) Disney HQ, New York, 4 Hudson Square, New York – Rooftop Boiler Exhaust Stream Simulation

Figure 6: TRX, Retail Plot 1, Kuala Lumpur – Odour Concentration Contours

Related Articles:

https://windtechconsult.com/john-hunter-health-and-innovation-precinct-jhhip-newcastle-nsw-helipads/