Embodied Carbon Reduction in Buildings: The Role of the Wind Engineer

Posted on April 9, 2025

As the building and construction industry evolves in response to climate imperatives, the focus is rapidly expanding beyond operational efficiency to include embodied carbon—the emissions associated with the materials and construction processes used to bring a building to life.

Governments, certification bodies, and developers worldwide are setting ambitious targets for carbon reduction. Yet one often-overlooked contributor to embodied carbon savings is the wind engineer. By optimising a building’s aerodynamic performance early in the design process, it’s possible to reduce the structural demands—and in turn, the materials needed—without compromising on design or functionality.

At Windtech Consultants, we’ve worked on over 3,000 projects globally and have found that strategic aerodynamic interventions and advanced methods can lead to construction cost savings and embodied carbon reductions of 10–20% or more.

The Global Carbon Context

The call for embodied carbon reduction is coming from all corners of the world. Here are just a few examples of frameworks driving this change:

-

-

- European Union: The EU’s Whole Life Carbon Roadmap aims to make life cycle emissions reporting mandatory by 2027, with full carbon performance limits by 2030.

- United States: The Inflation Reduction Act (IRA) includes funding for low-embodied-carbon construction through programs like the Federal Buy Clean initiative.

- Singapore: The Green Building Masterplan targets 80% of all buildings (by gross floor area) to be certified under the BCA Green Mark Scheme by 2030, with embodied carbon assessment included.

- World Green Building Council: Its Advancing Net Zero program calls for all new buildings to be net-zero operational and embodied carbon by 2030 and all new and existing buildings by 2050

-

These policies represent a growing shift: it’s not just how we operate buildings that matters—it’s how we build them.

Why Wind Matters in Carbon Reduction

The link between wind loads and structural materials is direct. Higher wind loads require heavier structural systems, which increases both cost and embodied carbon—especially in concrete and steel.

By engaging wind engineers early in the design process, developers can make subtle form adjustments or staging decisions that reduce wind loads, allowing the structure to be leaner, lighter, and lower in emissions.

Case Study 1: SRG Tower, Dubai

13,100 Tons of Embodied Carbon Saved Through Aerodynamic Refinement

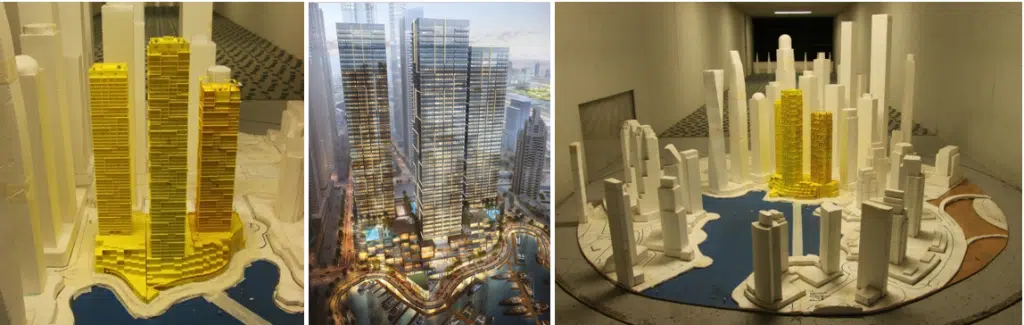

SRG Tower, a 350-metre residential tower in Dubai’s city core, exemplifies how early aerodynamic optimisation can drive down embodied carbon.

Figure 1. Coherent Vortex Shedding of a Square Plan Building

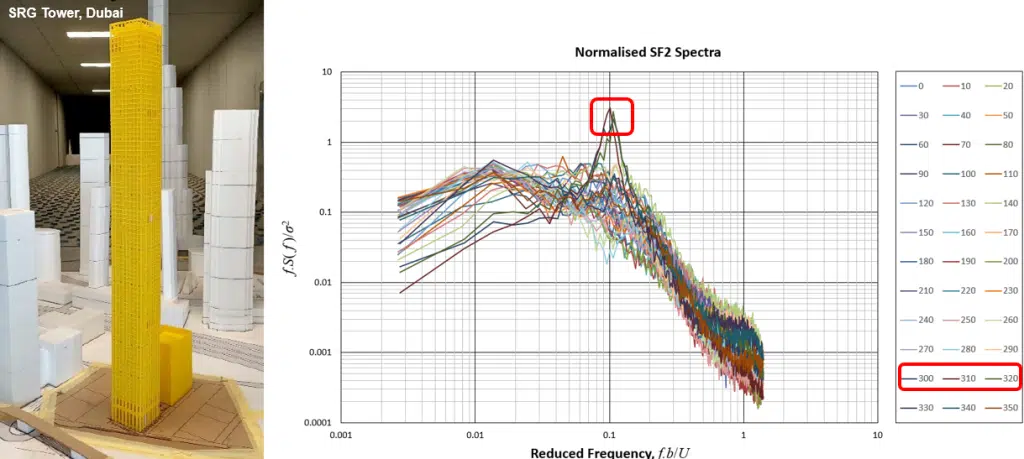

The original scheme featured a square plan with an extremely slender profile (aspect ratio 12:1), rising to 1150 feet. Wind tunnel testing revealed significant cross-wind excitation—particularly around the 310° wind direction, which aligns with Dubai’s prevailing wind. The issue was traced to vortex-induced oscillation, a common phenomenon in slender towers, where wind vortices shed alternately from either side of the building, causing sway.

Figure 2. Response Spectra Showing Excitation at 310° and Adjacent Angles

The architect and developer were averse to significant alterations to the architectural form, which constrained Windtech to find a more subtle solution. The team ruled out using tuned mass dampers, reducing the building height, or implementing large cutouts due to concerns over cost, delays, and loss of floor area.

Windtech proposed a dual-strategy approach:

-

-

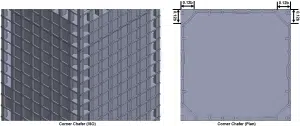

- 1. Slotted Corner Chamfers – Small chamfers at the building corners, approximately 12% of the width between columns, were introduced. This disrupted the formation of coherent vortices without affecting the architectural elevation or internal layouts. The distance was carefully chosen based on extensive precedent where chamfers exceeding 10% of building width have consistently improved cross-wind performance.

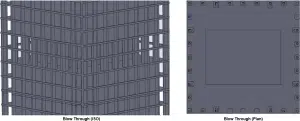

Figure 3. Recommended Corner Chamfers2. Open Service Floors – Strategic placement of open floors at specific levels allowed the wind to pass through, further reducing the dynamic suction effect on side walls. The number of such floors was minimised to maintain leasable area and building efficiency.

Figure 4. Recommended Blow-through Holes

- 1. Slotted Corner Chamfers – Small chamfers at the building corners, approximately 12% of the width between columns, were introduced. This disrupted the formation of coherent vortices without affecting the architectural elevation or internal layouts. The distance was carefully chosen based on extensive precedent where chamfers exceeding 10% of building width have consistently improved cross-wind performance.

-

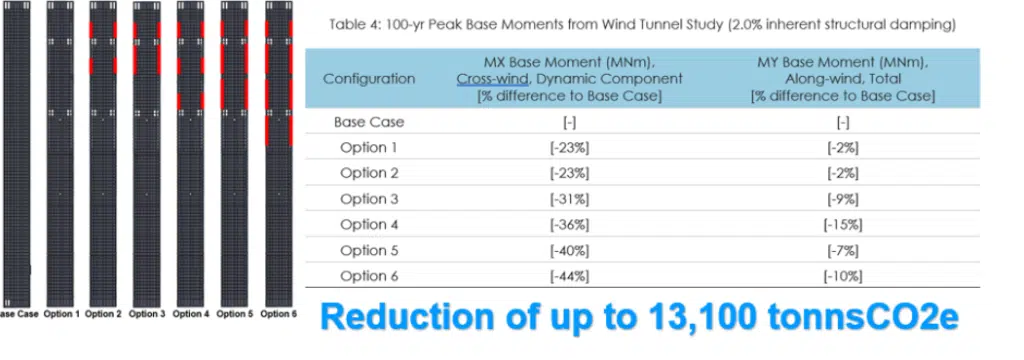

A parametric study involving six different treatment configurations was performed using a single physical model, cleverly adapted with masking tape to toggle configurations. This enabled rapid testing and accurate comparisons.

Figure 5. Parametric Study of 6 Design Options (Red: Corner Chamfer)

Results:

-

-

- The peak base moments, which are governed by the crosswind response, are reduced by up to 44%

- The structural team could reduce reinforcement and concrete mass across the entire superstructure

- An estimated 13,100 tons of embodied carbon was eliminated—excluding foundations, where further reductions were also achieved.

-

This was accomplished without changing the building’s visual identity. This case is a textbook example of how wind engineers can work within tight design constraints and still deliver major carbon savings.

Case Study 2: High-Rise Development, Dubai

14,200 Tons of Embodied Carbon Avoided with a Simple Change in Construction Staging

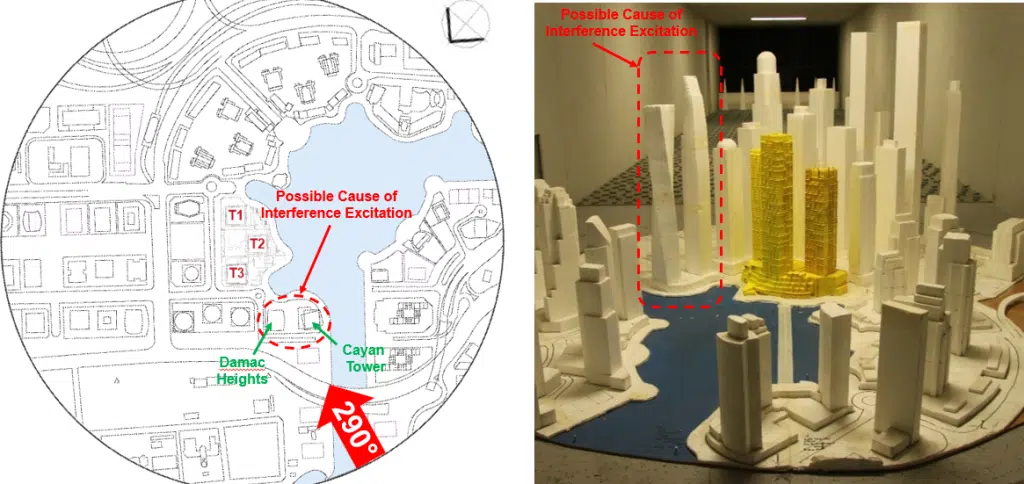

In a separate Dubai-based development, Windtech’s wind engineers were engaged to study a high-rise precinct involving several towers of varying height and orientation. Upon testing, one tower—Tower 2—displayed unexpected wind-induced excitation at the 290° wind direction.

Figure 6. Image of Marina Gate, Dubai is one of Windtech’s Wind Tunnels

Initial analysis showed that the tower wasn’t being excited by its own shape, but rather by interference effects from nearby completed towers, particularly the adjacent Cayan Tower and Damac Heights.

Figure 7. Interference Excitation Caused by Cayan Tower and Damac Heights

The response levels exceeded acceptable comfort and performance thresholds, and without intervention, would have required a costly and time-consuming redesign. This could have meant thicker core walls, more structural bracing, or even changes to the tower’s height or orientation—all options with significant embodied carbon implications.

However, there was a twist: Tower 2 was scheduled to be built before Tower 3, even though Tower 3 was positioned in such a way that it could disrupt the wake turbulence causing the problem.

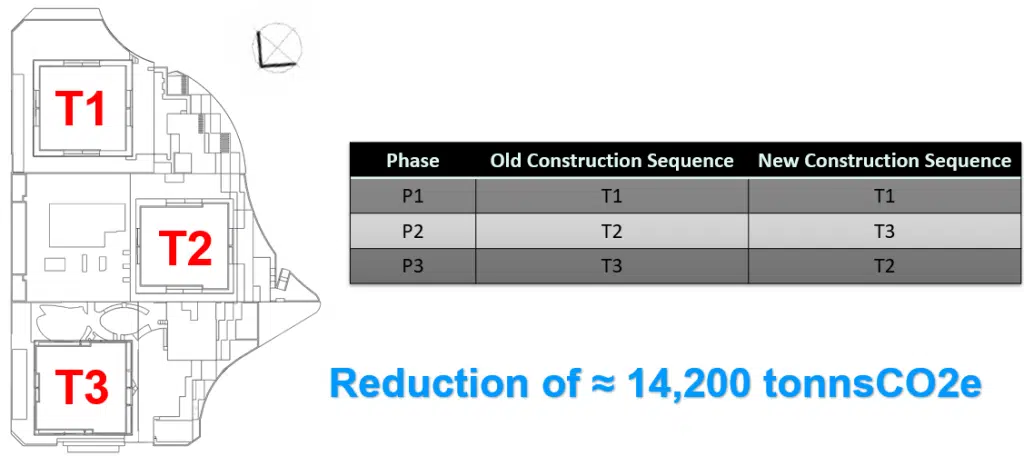

Windtech proposed a simple but effective solution—reverse the phasing and build Tower 3 first.

Figure 8. Revised Construction Sequencing

When tested with Tower 3 in place, the aerodynamic interference was drastically reduced:

-

-

- 36% reduction in base moments for Tower 2

- Wind excitation dropped below design thresholds

- The structural scheme for Tower 2 remained unchanged

-

This avoided a complete overhaul of the structural design and saved both time and materials.

Result:

-

-

- Approximately 14,200 tons of embodied carbon avoided, mostly in the form of concrete and rebar that would otherwise have been added to strengthen Tower 2

-

This case highlights how a minor change in construction sequence—guided by wind engineering analysis—can deliver major sustainability wins with no impact on design or project schedule.

The Hidden Power of the Wind Engineer

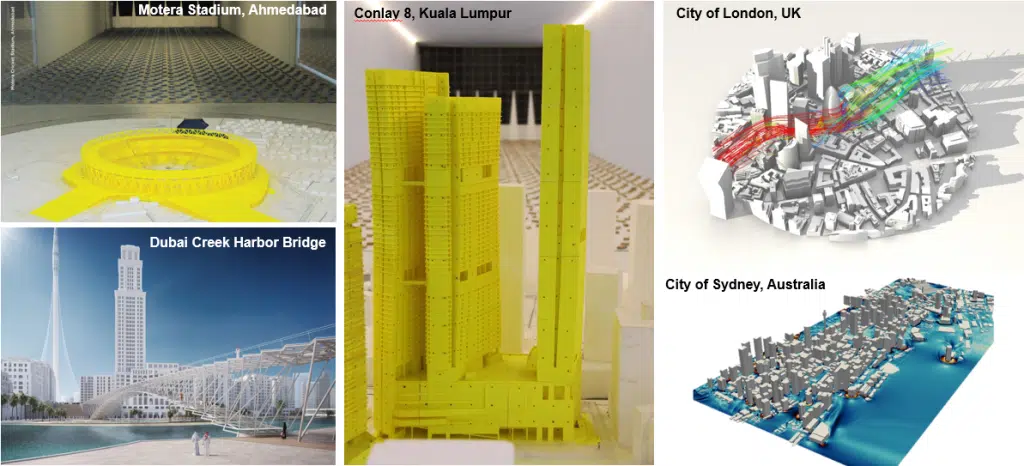

Windtech’s work across Asia, the Middle East, Europe, and North America has shown that the best carbon reduction strategies are often the least disruptive. Tools we commonly use include:

-

-

- Aerodynamic optimisation

- Construction sequencing

- Ensuring that the effect of modal coupling is considered.

- Rigidly Linking Buildings

- Using advanced methods of accounting for the directionality in the wind climate.

- Considering the effect of positive aerodynamic damping.

- Generating Time Series Load Cases in lieu of Static Load Case

- Incorporating auxiliary dampers for the very slender/ dynamic structures

-

When applied at the concept or schematic stage, these strategies can significantly improve the project bottom line, reduce the amount of embodied carbon and avoid post-design fixes or costly retrofits.

Conclusion: Wind Engineering as a Decarbonization Tool

As the global building industry works toward carbon neutrality, embodied carbon is becoming a central concern. The wind engineer—once seen primarily as a compliance partner for occupant comfort—is now emerging as a key ally in achieving net-zero carbon goals.

When developers engage wind engineers early, they unlock the opportunity to:

-

-

- Reduce structural material volumes

- Cut embodied carbon by tens of thousands of tons

- Avoid costly redesigns or remedial measures

- Stay aligned with global regulatory frameworks

- Preserve design vision and construction timelines

- Improve the overall project bottom line

-

At Windtech, we believe in designing smarter, not heavier. As we move toward a low-carbon future, the role of the wind engineer will only become more critical in ensuring that buildings are both resilient and responsible.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

Return to Main News Page