Engineering Efficiency in Motion: Windtech’s Integrated Wind and Environmental Studies for 2150 Lake Shore Boulevard West, Toronto

Posted on October 29, 2025

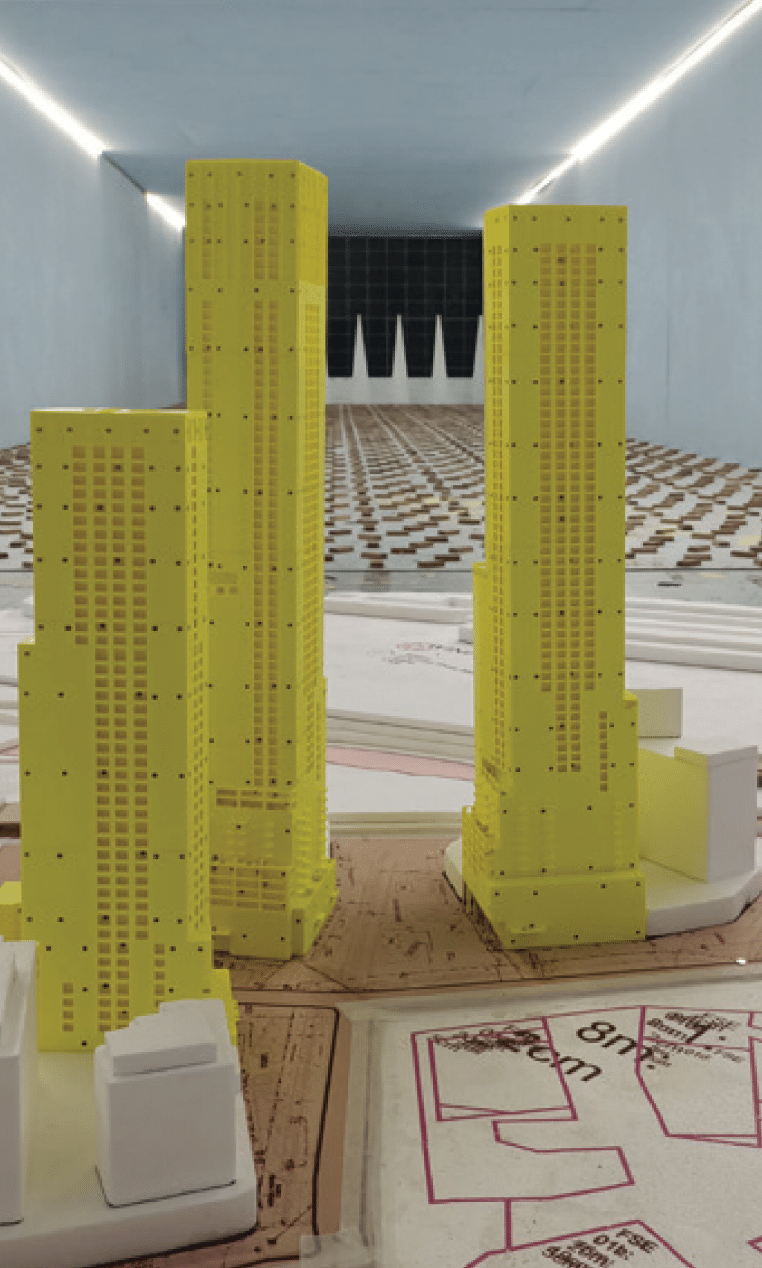

Figure 1. Aerial Image of Lake Shore Boulevard West Development

Occupying the 28-acre former Mr. Christie factory site, the development by First Capital REIT and Pemberton Group will transform the western lakeshore into a mixed-use, transit-oriented precinct anchored by a new integrated GO Station and TTC Hub. The plan includes multiple residential and commercial towers—several exceeding 200 m in height—together with retail, offices, and extensive public realm improvements that reconnect the city with the waterfront.

Windtech’s wind engineers delivered comprehensive wind tunnel testing, wind-induced structural load and motion testing, and façade cladding pressure studies for the first 3 towers, all conducted in its Sydney-based boundary-layer wind tunnel, utilising the firm’s advanced multi-sector analysis method to post-process the results. Windtech also conducted thermal stack-effect assessments for the towers. The studies were instrumental in shaping an aerodynamically efficient design that met stringent comfort and serviceability criteria while minimising material use, cost, and embodied carbon.

Precision Engineering and Performance-Based Design

The studies covered Towers C1 (154 m), D1.1 (223 m), and D2.1 (212 m), all slender residential structures rising from shared podiums.

- Structural response:

- D1.1 and D2.1 were governed primarily by cross-wind excitation, while the response of C1 was governed by along-wind effects

- Peak tip deflections for all towers were within the H/500 serviceability limit, confirming optimal stiffness.

- Accelerations under 1- and 10-year winds met the comfort thresholds defined by ISO 10137, without the need for supplemental damping devices.

Windtech’s multi-sector analysis of climate directionality proved pivotal in demonstrating that these slender towers can meet the limits on tip deflections and occupant comfort. By integrating aerodynamic responses across the various wind sectors, our wind engineers avoided the built-in conservatism inherent in sector-by-sector analysis.

This precision offered more than data accuracy; it was a form of risk mitigation. For towers operating near their motion limits, the ability to identify the exact wind sectors driving those peak responses allowed the structural engineer to fine-tune the structure without resorting to conservative redesign. In practical terms, the analysis avoided the need for costly supplemental dampers or structural thickening that often follows when less-sophisticated directional methods are used.

The outcome was a set of refined equivalent static load cases that faithfully represented the true aerodynamic behaviour of each tower, supporting both design confidence and material efficiency, a rare combination in high-rise performance engineering.

Cost and Embodied-Carbon Efficiencies

The design optimisations derived from Windtech’s wind tunnel testing resulted in substantial material savings. By proving that the towers could perform safely within serviceability and comfort criteria with no significant modification to the proposed structural system, the engineers eliminated the need for additional stiffening of the cores or the introduction of heavy outriggers, leading to:

- Reduced embodied carbon through lower volumes of concrete and steel.

- Smaller foundation loads, enabling leaner substructure design.

- Avoidance of mechanical damping systems cuts not only capital cost but also long-term maintenance and operational carbon footprint.

These efficiencies demonstrate how performance-based wind design/testing can drive both economic and environmental outcomes—a key advantage in the development of this scale.

Façade and Environmental Studies

A wind tunnel study of the façade pressures used more than 1,000 sensors to map localised load effects across façades, balconies, soffits, and podium elements. Contours of maximum and minimum net pressures are presented in the report in a format that facilitates the design of the cladding and glazing systems.

Figure 2. Close up photo of the instrumented models in Windtech’s boundary layer wind tunnel facility

Meanwhile, stack-effect modelling identified wintertime pressure differentials at elevator lobbies and podium entries. Mitigations such as added vestibules and segmented lift lobbies were incorporated, ensuring occupant comfort and efficient HVAC operation year-round

A Holistic, Low-Impact Outcome

By integrating aerodynamic optimisation, façade pressure mapping, and environmental airflow analysis, Windtech’s wind engineers enabled the project team to achieve high-rise resilience with minimal material intensity. The studies ensured:

- Verified compliance with serviceability and comfort criteria, even near threshold conditions.

- Embodied-carbon reductions through right-sizing of structural elements.

- Cost savings from eliminating unnecessary dampers and superfluous structural mass.

The 2150 Lake Shore Boulevard West development now stands as an exemplar of how advanced wind engineering can align sustainability, performance, and design economy, proof that smart data beats brute strength.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

Return to Main News Page