How Wind Tunnel Testing supported the construction of Terminal F at Dallas Airport

Posted on August 28, 2025

Figure 1: Perspective Image of Terminal F at Dallas-Fort Worth Airport

When Dallas Fort Worth International Airport set out to build Terminal F, it wasn’t just adding another gate; it was engineering a solution to handle 100 million passengers annually by 2030. However, with a massive long-span roof and a complex skylink system, traditional wind load calculations wouldn’t suffice.

That’s where Windtech Consultants stepped in, working alongside PGAL Architects, Innovation Next+, and Turner to solve what would become one of the most sophisticated wind engineering challenges in modern airport design, using state-of-the-art wind tunnel testing.

The Challenge: Beyond Standard Analysis

Terminal F presented a unique engineering puzzle. The expansive terminal structure and elevated skylink system created complex wind interaction patterns that standard approaches couldn’t adequately predict. The long-span upper roof, positioned at the terminal’s heart, demanded a level of precision essential for the project’s structural efficiency.

Traditional analysis methods would have resulted in overly conservative designs, which would have driven up costs and potentially compromised the architectural vision. The team needed something better.

The Solution: Wind tunnel testing using the Multi-Sector analysis technique

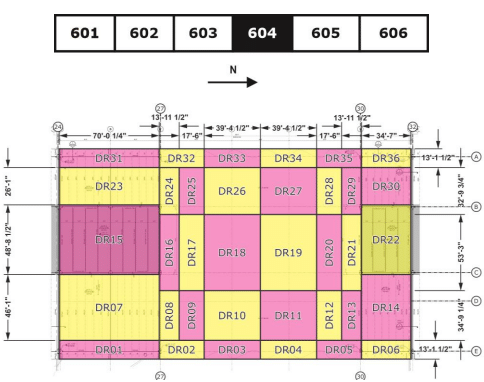

Windtech adopted the multi-sector analysis technique, which is the most rigorous method of combining the wind tunnel testing pressure coefficient data with the local wind climate model. In addition, the area-averaging method was used to accurately determine the loading on the main structural members, an industry-recognised approach for translating detailed wind tunnel testing data into actionable design loads. Rather than focusing on isolated peak pressures at individual points, the area-averaging method considers the combined effect of pressures distributed across larger panels of the structure as indicated in Figure 2. This provides a more realistic representation of how these large structural members experience wind actions.

By carefully defining representative panel sizes and shapes across the terminal envelope, our team delivered wind-induced load cases that accurately reflect the building’s true behaviour under extreme winds from different directions. The outcome: reliable, rationalised pressure distributions that give the structural engineer confidence, avoid overly conservative assumptions, and contribute to a more efficient, cost-effective design.

Figure 2. Panel Layout for Roof of Sector 604 of Terminal F at DFW

Comprehensive Wind Engineering

The scope extended far beyond structural loads. Windtech conducted exhaustive facade cladding pressure studies across every surface of both the terminal and skylink system, ensuring no detail was overlooked. A comprehensive wind tunnel testing process and wind microclimate assessment evaluated how the new terminal would affect ground-level conditions, protecting passenger comfort and operational efficiency.

Figure 3. Wind Tunnel Testing Model Terminal F at DFW

Solving the Solar Glare Puzzle

Aviation projects face a unique challenge that most buildings don’t: Federal Aviation Administration oversight of solar reflectivity. Terminal F’s modern facade and rooftop photovoltaic arrays required careful analysis to prevent solar glint and glare from affecting pilots during critical approach and departure phases.

Windtech’s Solar Light Reflectivity Analysis identified potential problem areas and guided design modifications, ensuring full FAA compliance while maintaining the terminal’s striking architectural aesthetic.

The Impact: Setting New Standards

Terminal F now stands as a testament to what’s possible when advanced engineering meets ambitious architecture. The project demonstrates how thoughtful wind tunnel testing and wind engineering can unlock architectural possibilities while delivering measurable value through improved structural efficiency. For an industry where safety, performance, and cost-effectiveness are non-negotiable, Terminal F represents the future of intelligent design.

Ready to tackle your next complex wind engineering challenge? Discover how Windtech’s innovative wind tunnel testing approaches can transform your project’s performance and efficiency. Please contact our regional offices through our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page

Return to Main News Page