Wind Tunnel Testing India

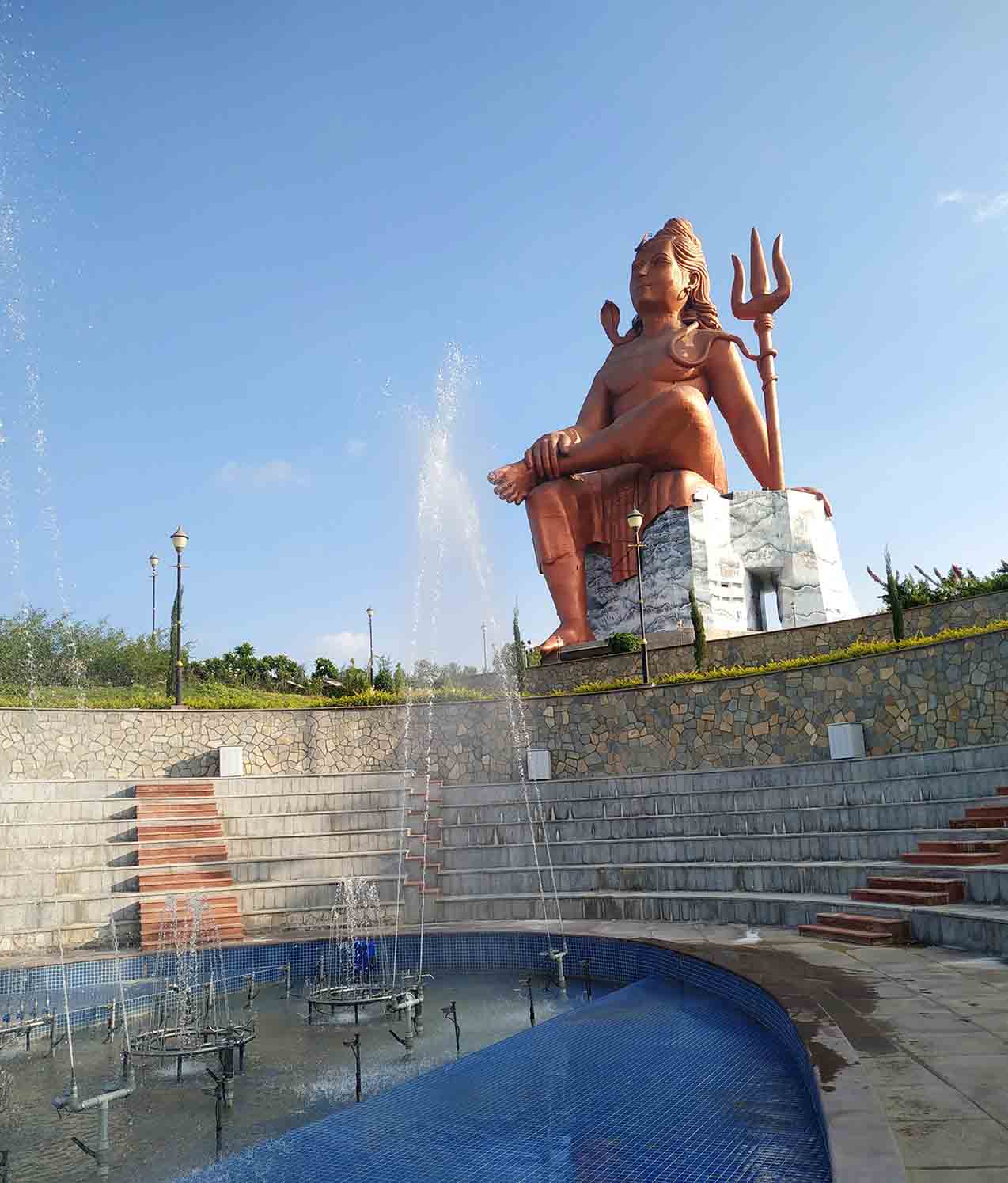

Shiva Statue, Nathdwara

Shiva Statue by Miraj Group is the world’s largest statue of Lord Shiva. The foundation stone was laid by PujyaMurariBapu in presence of the Rajasthan Chief Minister Ashok Gehlot in Ganesh Tekri area of the Nathdwara, India on 18th August 2012.

Windtech Consultants has extensive experience in the study of wind effects on special structures in India. Wind engineering is essential to access unusual wind-sensitive structures, both large and small, require special modelling to accurately account for the wind loads experienced. This requires detailed knowledge of the limitations and principles behind wind tunnel testing for complex designs, often requiring case specific methodology and a detailed testing program to arrive at the most accurate possible results.

Windtech Consultants undertook wind tunnel testing in India for the initial scheme for the statue of Shiva in Nathdwara, India. Upon its completion, the statue will be the tallest in India and one of the tallest in the world rising to 107m (351ft) above ground.

Windtech’s wind engineers used sophisticated modelling techniques to fabricate the model. This involved using a 3D scanner to digitise the physical sculptural model into a virtual point cloud which was converted into a surface with thickness. The model was then printed using in-house 3D printers to form the exact shape at 1:200 scale. A larger scale model was fabricated to conduct a dynamic analysis on the trident structure.

Wind tunnel testing was first carried out using a scale model of the statue to determine the effect of the surrounding structures on the upstream velocity and turbulence intensity profile for wind incident from different wind directions. These wind profiles were replicated at full scale to be used for this wind study. Our wind engineers carried out an extensive analysis of the wind climate for Nathdwara, India.

A structural loads &motion study was carried out using both the high-frequency force balance (HFFB) and high frequency pressure integration (HFPI) techniques. These techniques were undertaken for both the main body and the trident structure. The use of the HFPI technique enables an accurate and definitive determination of the vertical distribution of the wind loads. The use of the HFFB was employed as a quality control check on the HFPI analysis and confirmed an extremely good match. An analysis of the aerodynamic instability risk for the trident structure was also carried out.

A Façade Cladding Pressure study was undertaken for the statue to obtain the full-scale pressure distribution over the entire statue envelope. The pressure contours were presented in 2D format in the report as well as on a virtual 3D model in “block contour” format which is a unique capability to Windtech Consultants.

Need help with an upcoming project? Don’t hesitate to contact our dedicated Global Wind Engineering team, who will gladly assist. With offices in Sydney & Melbourne, Australia, London, UK, and Mumbai, India. New York & Miami, USA, Dubai, Hong Kong & Singapore, we guarantee to support you wherever you are based.