Wind Tunnel Testing India

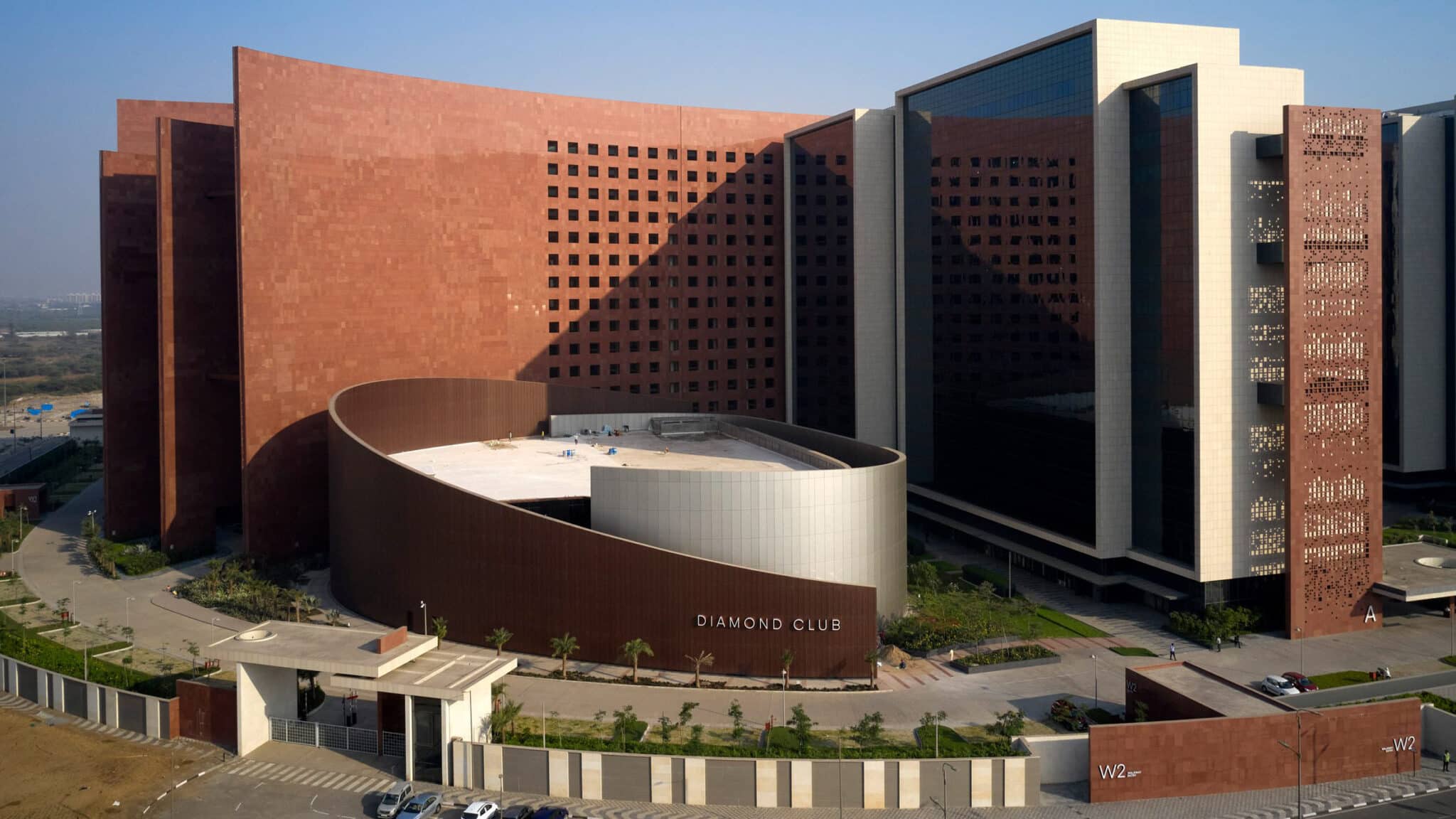

World’s Largest Office Building: Surat Diamond Bourse

The Surat Diamond Bourse is a remarkable structure that redefines architectural possibilities and a symbol of contemporary architecture and engineering. Emerging as the world’s largest office building, surpassing even the Pentagon in size, this remarkable structure redefines architectural boundaries. Comprising a sequence of nine interconnected rectangular modules that radiate from a central “spine,” this sprawling 15-story complex occupies over 35 acres. Notably, its distinctive design is highlighted by a substantial standalone blade wall, a key architectural element.

Figure 1. Surat Diamond Bourse Building

Windtech’s specialized wind engineering services played a pivotal role in safeguarding the structural integrity of this innovative masterpiece, with unique analysis required to determine the wind actions on the blade walls. Aaron Lefcovitch, a Director of Windtech, indicated that “The blade walls are not too dissimilar to stadium roofs or large canopies in that they fall into the same category of structures known as Long-span structures. Long-span Structures are inherently sensitive to the forces of wind due to the extent of the area exposed to the wind, relative light weight, and low stiffness. Unlike tall buildings, it becomes exceedingly more difficult to determine the loads on these structures using a code-based approach, especially when the natural frequency of the structure is lower than 0.8Hz.

There have been numerous cases (e.g., WIN Stadium in Wollongong), where code-based design was unable to predict the critical asymmetric load cases that are dictated by a structure’s unique support system, resulting in design loads that do not reflect reality. The implication is a structural design that may not be adequate to resist the actual wind loads or is significantly over designed, affecting the aesthetics of the design or adding unwanted cost to the project during construction.”

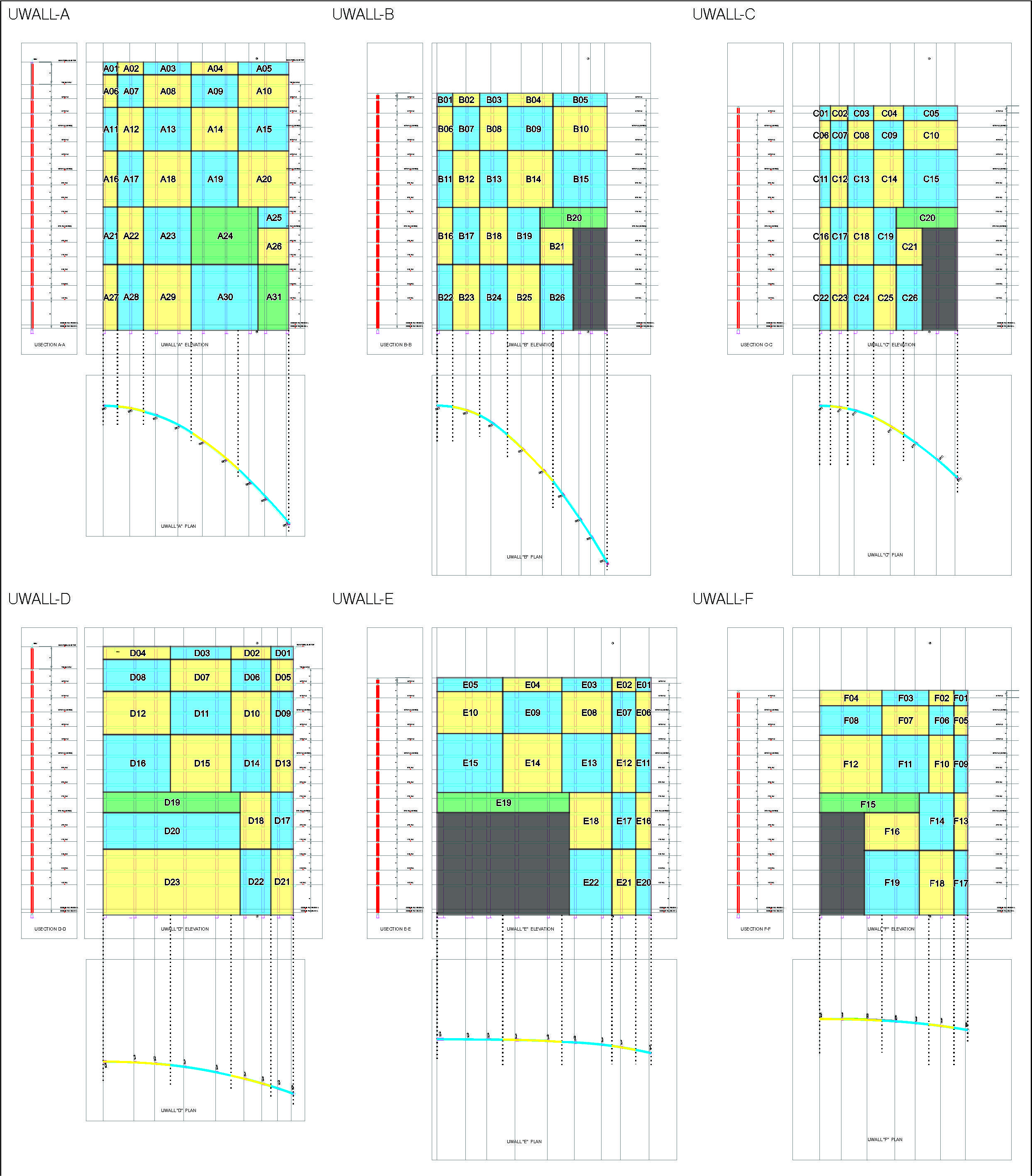

Figure 2. Blade Walls of the Surat Diamond Bourse Building

The long-span walls of the wind tunnel model were fitted with a total of 183 pressure sensors, divided into 83 panels as indicated in Figure 3. Several pressure sensors were assigned to each panel, and the time-series of the results from each pressure sensor, which are acquired simultaneously for all pressure sensors, are area-weighted to determine the average net pressure acting on each panel.

Figure 3. Blade Wall Panel Layout used for Load Cases

Critical load cases were suggested in this study to account for the various wind load combinations acting on the long-span wall structures. Once the various critical load cases were determined, these were applied by the structural engineer to the FEA model of the long-span wall structures, allowing them to adequately design the member sizes and lateral stiffeners that were used to make up the structural design.

Tony Rofail, Managing Director of Windtech, indicated that “There are many ways to determine wind loads on long-span structures depending on the client’s requirements. The simple area-averaging technique, as was used on the Surat Diamond Bourse project, is the simplest method. However, if the client is keen to optimize the structural design, we can offer the Load Response Correlation (LRC) method, also referred to as the Load Effect method. This method produces unique panel load case combinations linked to a set of different types of maximum and minimum Load Effects spread across the structure such as the the reaction force at a node, stress in a beam, deflection of a node, or any Load Effect that the structural engineer sees as being critical to the design of the structural system. It is more computationally intensive, but not subject to the same conservative assumptions seen in simpler techniques. We see it commonly used when clients wish to pursue more pure forms of performance-based design to reduce project costs, or when there is a requirement to minimise the structural member sizing from a design aesthetics point of view. The Load Effect method also allows us to account for resonant response effects, which is important when the natural frequency of the structure falls below 0.8Hz.

This project is a shining example of Windtech’s commitment to pushing the boundaries of wind engineering innovation and delivering solutions that shape the future of modern architecture.

If you are working on any projects that could benefit from the capabilities presented in this article, please reach out to our regional offices Sydney & Melbourne, Australia, London, UK, and Mumbai, India. New York & Miami, USA, Dubai, Hong Kong & Singapore, we guarantee to support you wherever you are based.

To get regular updates on news and events, please follow us on our LinkedIn page.