Smart Structures, Big Data

Posted on July 30, 2021

Telemetry is not a new concept, and in fact was explored by James Watt in the mid 1700 when he added devices such as the mercury pressure gauges and the fly-ball governors to his steam engines; both classic examples of devices that would reveal something important about the performance of a system. The person consuming the data (in this case the operator of the steam engine) could then determine the best course of action depending on the “state” of the system in question.

Since then, monitoring has become commonplace across all industries due to the rapid progression of available technologies which were, in the recent past, only reserved for industries that were exposed to high capital expenditure or where there was a strict requirement to secure a high value asset. Nowadays these technologies are available to a broader spectrum of industries due to a significant reduction in cost. Further, with proliferation of Internet of Things (IoT) and universal communication protocols, these systems are no longer confined to Local Area Networks (LANs) but can be quickly and easily connected to the world wide web. This then opens the opportunity for a wealth of information that can be read in conjunction with (or correlated to) the main data that monitoring system was designed to produce.

It is then no surprise that the construction industry has recently been quick to adopt such technologies. One emerging application is in the area of Structural Health Monitoring (SMH), which is applicable to a range of different sub-industries as follows:

- Infrastructure (i.e.large public works, dams, bridges, highways, railways, water or wastewater, tunnels, subways, radio towers),

- Building construction (i.e.residential and commercial buildings, worksite), and

- Industrial construction (i.e.offshore construction (mainly of energy installations), mining and quarrying, refineries, chemical processing, power generation, mills and manufacturing plants)

Another catalyst for the adoption of SHM in the construction industry has been the implementation of policies in various building codes. For example, the Indian Standard IS16700 “Criteria for Structural Safety of Tall Buildings” Clause 11 stipulates that a building taller than 150m shall be instrumented with accelerometers to monitor the impact that seismic and wind load have on the structural health. Further, Circular No. 01-2015 “Guidelines for implementing Rules on Earthquake Instrumentation for Buildings” which expands the scope of the P.D. 1096 “National Building Code of the Philippines (NSCP)” provides criteria on what types of buildings in seismic zones of the Philippines should include structural health monitoring for the purpose of building response to seismic activity, and to provide real-time alerts to occupants so they can be moved to safety under the Building Emergency Evacuation Plans (BEEP) instituted by the National Disaster Risk Reduction Management Council (NDRRMC).

SHM provides a platform to surface data that diagnoses the “state” of the constituent materials, parts, and assemblies that make up the total system. The central ideology is that the structure should perform within the bounds specified by the initial design, although some flexibility should be allowed for performance creep due to aging and/or general ware and tare of the structure. This is quite normal during the first 2-3 years of life given materials and/or structural systems bed themselves in which is more related to changes under normal serviceability conditions. However, there can be significant impacts on structural performance when a building or structure is hit by an extreme event (i.e. wind, seismic or other extreme events) where the actual load approaches the design load resulting in drastic changes in the structural performance due to the rapid degradation of the structure. This degradation could exhibit itself in many ways depending on the type of damage and/or the structural resilience. An example of degradation could be the on-set of micro cracking in concrete, which would increase total system damping while reducing the natural frequency. One of the ways to be able to pick up this effect could be to measure time-history response data using a highly sensitive accelerometer to log the change in the frequency of oscillation and the time to decay. This information can be plotted on a timeline to yield and indication of progressive or sever changes in the structural performance. Measured data can then be correlated with data from other sources either locally or externally (i.e.wind speed data) to allow for a diagnosis the reason why the structure was performing outside the normal parameters, thus helping to dictate strategies around service and maintenance.

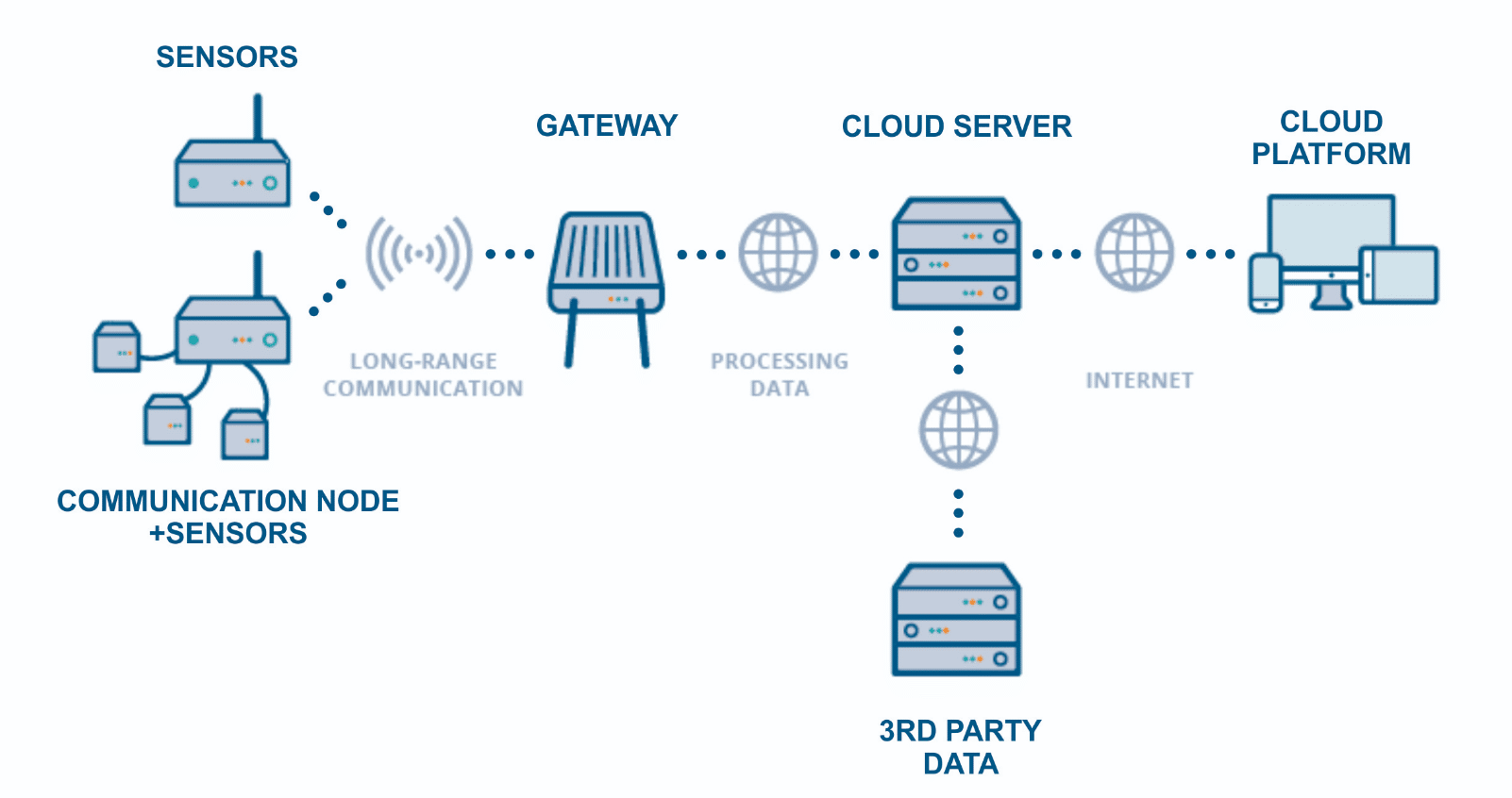

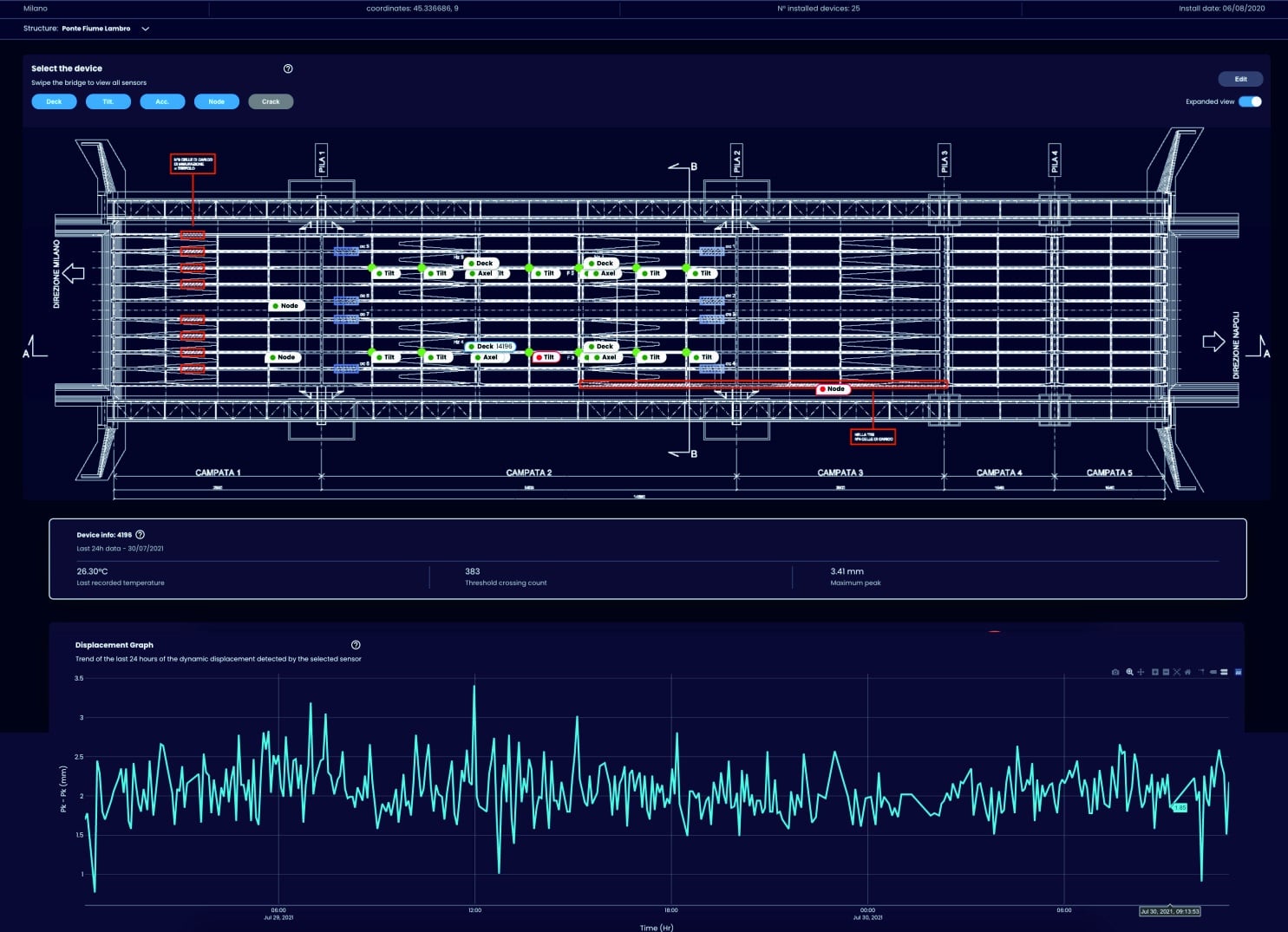

SHM can be seen as a new way to conduct non-destructive evaluation. Further it may not be limited to monitoring a single data point at a single location, but rather a string of data points over time from vast array of sensors of different type and location in order to paint a complete picture of the structural health. Although the design of SHM system can vary depending on the individual project requirements, this tends to follow the typical blue print indicated in Figure 1, where a mixture of sensors feed data into digital or analogue nodes which transmit the information to a gateway. The data is then processed and formatted, sent via the internet to a cloud server and consumed via cloud platform that helps the user navigate the data in a structured way. An example of a cloud platform can be seen in Figures 2a and 2b. In addition to the consolidation of local sensor data, 3rd party information (i.e. regional wind climate data) can be fed into the system to enrich the underlying data model.

Figure 1. Structural Health Monitoring Blueprint

Some sensors that are being used in the industry, and by Windtechcan be seen below:

- Load Cell

- Crack-meters

- Accelerometer

- Strain Gauges

- Tilt-meter

- Temperature Sensor for Structural Elements

- Weather Station – (Temperature, Humidity, Wind Speed)

- GPS Sensors

- Level Monitoring Prisms

- Inductive & Pressure Sensors

- Corrosion Sensor

Figure 2a. Cloud Platform Showing Real-time Acceleration Time Response Data

Figure 2b. Cloud Platform Showing Real-time Displacement Data

Aaron Lefcovitch a Director at Windtech based out of the Singapore Office indicated that “knowing the health of a structure, whether it is a tall building, or a long-span bridge provides multiple benefits. It allows for manufactures, owners, end users, building designers and maintenance teams gain real-time insights into the performance of their assets. We are now able to stream and process large amounts of data using available technologies to foster informed decisions. This allows us to ensure that assets are performing within the design parameters. Data can be analysed in real time and can trigger events or notifications that instantly allow performance-based (or condition based) decisions. This reduces the cost of labour, human error, inspection costs and rectification work where there in some cases be no material defect. It also increases the value of the structure or asset, improves structural reliability and enables the implementation of effective performance-based design approaches which have major impacts on both the robustness and efficiency of the structure, and cost of construction. It also allows for building designers to collect full-scale data, so they are able to compare and fine tune their theoretical models and analysis techniques. The benefits are really limitless”.

SHM has ushered in a new era for construction industry. The concept of smart or intelligent materials/structures has become more present in the minds of designers and is being embraced by private and government institutions around the world as being a significant step forward in the general evolution of the construction industry. Windtech is proud to be part of this evolution with the implementation of their own solutions in the SHM space and will continue to encourage the implementation of evidence or performance-based approaches at all stages of a project’s lifecycle.

To enquire about our solutions relating to Structural Health Monitoring, please reach out via our Contact us Page

To get regular updates on news and events, please follow us on our LinkedIn Page

Return to Main News Page