Wind on Solar Arrays: Reduce Construction Costs & Risk of Failure

Posted on January 31, 2022

According to the International Energy Agency (IEA), renewable energy is expected to overtake coal as the primary means of electricity production by 2025, with solar energy expected to lead the surge. Currently, solar is already the cleanest and most abundant energy source, on top of being the cheapest in most countries.

Despite supply-side disruptions to solar panels and assemblages due to COVID-19, according to the IEA, global solar photovoltaic (PV) capacity additions to hit almost 107 gigawatts in 2020 – more than half of all renewable capacity additions for the year – indicating stable growth from 2019 numbers.

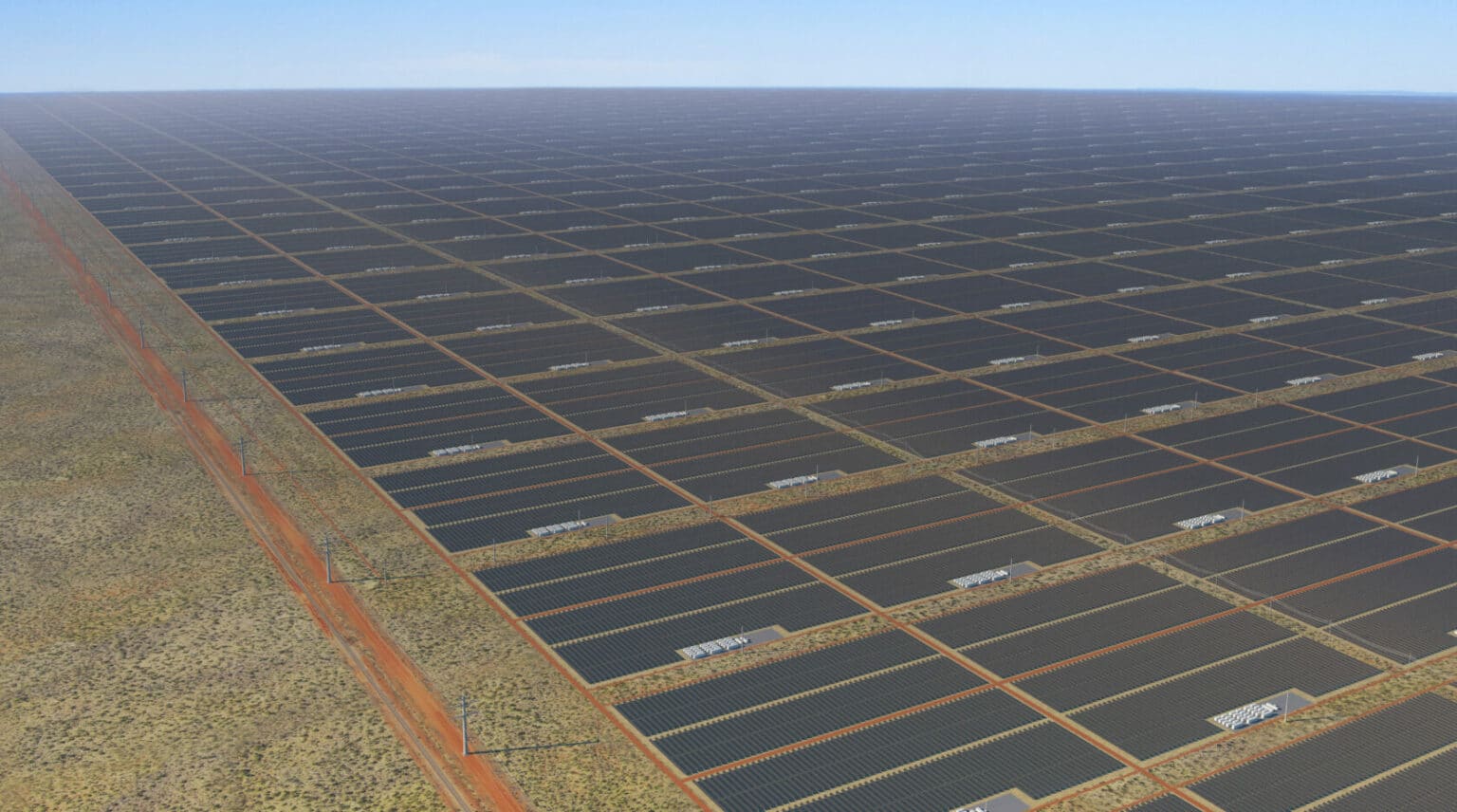

Figure 1. Proposed Sun Cable Solar Farm located in the Northern Territory, Australia

Large solar infrastructure projects are being rolled out all over the word on a scale never seen before with some solar farms (i.e. Sun Cable located in Australia) in development targeting between 17 to 20 gigawat-peak (GWp) of Electricity, part of which will be stored on-site in what is planned to be the world’s largest battery at 36 to 42 gigawatt-hours.

With the expansion of solar infrastructure projects some larger than ever before, developers, owners, operators are in the throes of learning from past experiences, in an industry that is rapidly changing with higher demands placed on engineered solutions to make projects of this size sustainable from a development and operational perspective.

Reliable wind loading information on solar panels is essential for the efficient large-scale deployment of solar infrastructure. However, only a limited amount of published data from wind tunnel studies is available to address aerodynamic loading information for these assets. Because of this knowledge gap, no provisions exist in the current building codes and standards for the design of PV mounting systems in areas that are vulnerable to extreme winds. As such, the only viable way to address this is through establishing the appropriate data on a project-to-project basis through quantitative methods using robust wind tunnel testing techniques.

Aaron Lefcovitch, Director of Windtech based out of our Singapore Office states “We are having an increase in enquiries relating to wind related issues for solar farms. Some clients are commissioning us to understand how they can secure their assets though the accurate prediction of wind loads on the panels themselves, which are inherently light, wind sensitive structures, some of which tend to exhibit complex dynamic behaviour under fluctuating wind loads. We develop scaled models placed in the wind tunnel to determine the underlying aerodynamic coefficients, then combine this data with an analysis of the regional wind climate, which is unique to the region where the solar farm is located. This is usually done during the design/development of a solar farm, however for some clients we need to get involved from a remedial perspective due the failure of the asset(s) under wind load. One thing becomes immediately apparent when embarking on a remedial study, which is the absence of a proper Performance-Based Design (PBD) approach which could have saved the asset from performance degradation or even downtime, and expensive repair bills.”

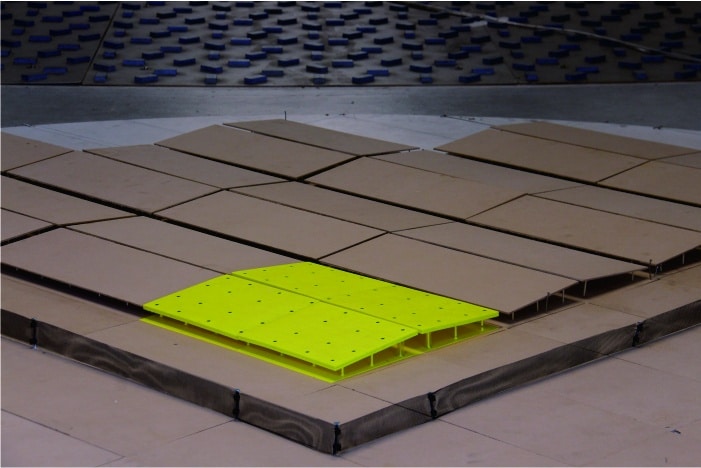

Figure 2. Al Noor 1.2GQ Solar Plant, Abu Dhabi

Windtech has been working on solar infrastructure projects for more than 15 years including some of the world’s largest solar farms built to date for example the Al Noor Solar Plant which covers an 8 square kilometre plot of land in Abu Dhabi and generates 1.2GW of electricity, enough to provide power to approximately 90,000 residences. Projects of this size need careful planning to be able to efficiently evaluate the aerodynamic coefficients in the wind tunnel as these farms tend to occupy a vast area with irregular edge profiles. It may be cost-prohibitive to test each and every panel at a scale that would large enough to not exhibit scaling effects (i.e. wind flow structures that would naturally depart away from reality if a model is too small). Hence to address this, Windtech Consultants has developed a robust and efficient methodology that accounts for the various locations within the cluster and edge configurations. Furthermore, provided the upstream terrain and panel geometry remains the same between solar farm sites, the underlying aerodynamic coefficients that were determined in the wind tunnel can be reused for subsequent sites with adjustments for the local directional wind speeds. Therefore, the client can potentially conduct one wind tunnel test for multiple sites rather than conduct a wind tunnel test for each site. Following this approach has resulted in a large uptick in the number of Solar Infrastructure tested in our facility as clients take advantage of the significant savings on the cost of wind tunnel testing. This is indeed true of both ground-mounted or water mounted solar farms in standard fixed or solar tracker configuration, each having its individual challenges.

Figure 3. Testing Effect of Wind Fence on Leading Edge Corner Panels for Al Noor 1.2GQ Solar Plant

Current in-house capabilities in solar include the determination of load cases for the purpose of structural design through the use of rigid model and/or aeroelastic test methods. These capabilities are supported by a wealth of experience in being able to reliably predict the appropriate design loads as well as any potential aerodynamic instabilities of a solar panel system.

Windtech is proud to be contributing towards performance-based wind design capabilities for the Solar Infrastructure industry. If you are working on any projects that could benefit from this capability, please reach out to our regional office via our Contact Us page.

To get regular updates on news and events, please follow us on our LinkedIn page.

Return to Main News Page