Wind Tunnels

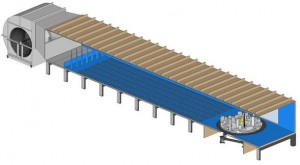

WINDECH owns and operates one of the largest boundary layer wind tunnel labs in the world with a total of 3 wind tunnels under one roof. Each wind tunnel is 3.0m wide, 2.0m high and has a fetch length of 23m.

Technology included at WINDTECH’s state-of-the-art labs includes:

- A large upwind plenum design in addition to common air straighteners for low turbulence testing of bridge decks and sections.

- A blockage tolerant test section, which reduces potential blockage effects occurring when the tested model is larger than normal.

- High fidelity pressure acquisition and processing systems.

- Highly accurate systems for measuring site specific wind speeds including hot-wire and cobra sensors which produce the most reliable wind speed data, particularly in highly turbulent flows.

- A range of different acquisition methods including the High Frequency Force Balance (HFFB), High Frequency Pressure Integration (HFPI) and Aeroelastic methods, which are commonly used for determining wind-induced loads on tall buildings.

- Varied methods depending the application for the analysis of wind loads on long-span structures including the simple Area Averaged technique and the more advanced Load Response Correlation (LRC) technique.

- Advanced section model rigs for testing bridge deck and cable aerodynamics.

- Full-scale façade mock-up rigs developed for quantitative testing of discharge coefficient, wind-noise generation, rain-noise, and the integrity of the facade elements under serviceability loads.

- The latest rapid prototyping of wind tunnel models using in-house 3D printers and CNC machines.

- Methods for demonstrating how wind flows around building bluff bodies using smoke visualisation.

- Live HD video broadcast via a secure portal, allowing clients and members of the consultancy team witness testing.

Windtech’s Wind Tunnel No.1 |

Windtech’s Wind Tunnel No.2 |

Windtech’s Wind Tunnel No.3 |